The production process in Odoo takes place in two stages:

1. Creating a task for a work shift

2. Display of the fact of production

Creating a task for a work shift

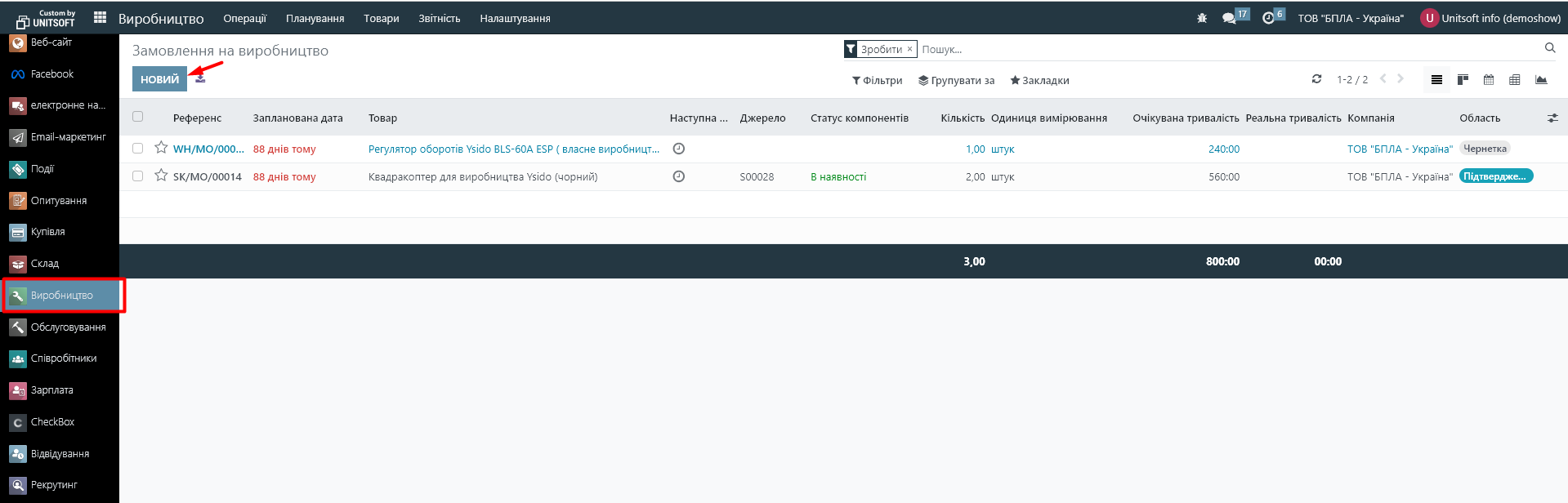

Go to the "Production" module - "Operations" - "Production order". Create a new document.

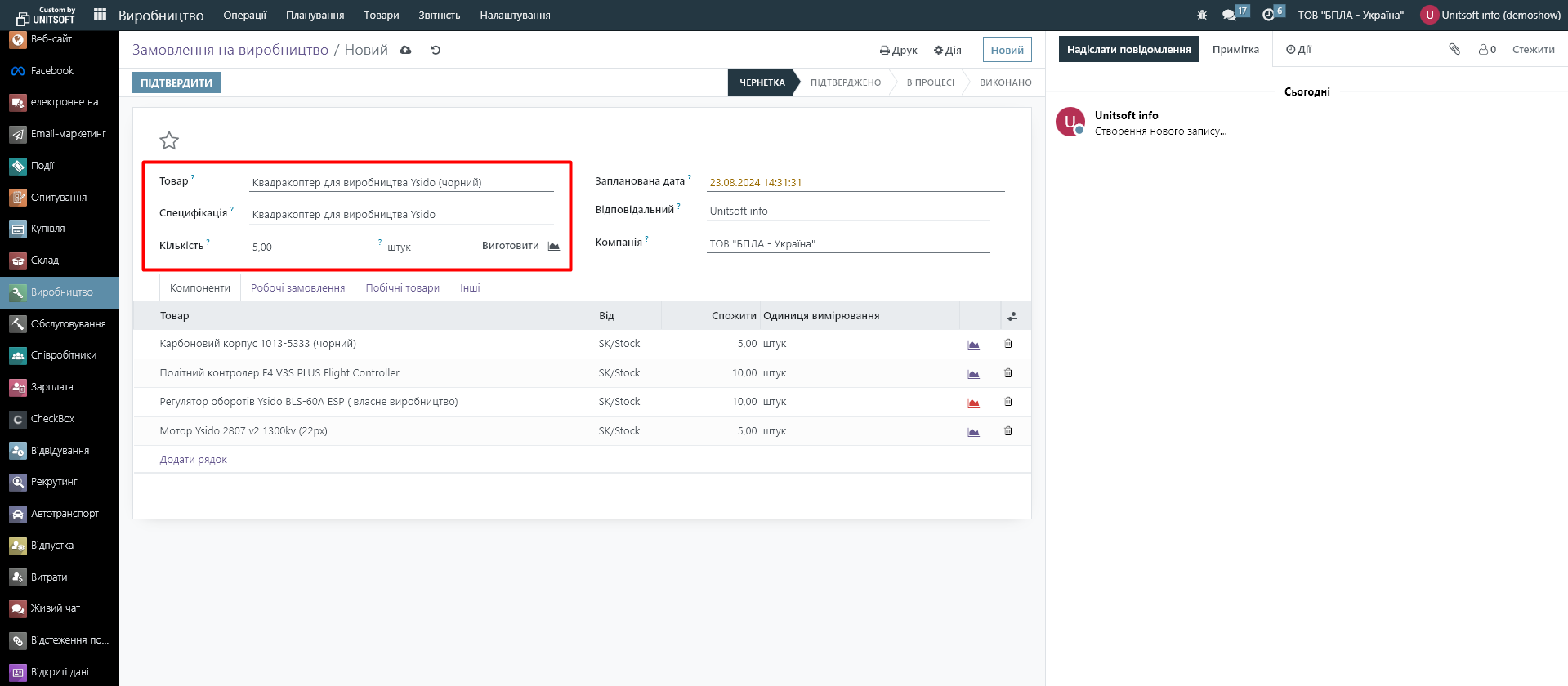

We indicate the name of the finished product and its specifications.

In the "Quantity" field, change the quantity of the product that we plan to produce.

Based on this information, the "Components" tab will automatically calculate the need for raw materials to manufacture the specified quantity of products.

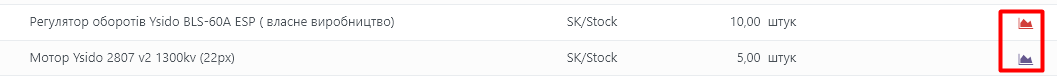

You can also see an icon that shows the availability of raw materials in the warehouse. Blue means that the raw materials are available in the warehouse, red means that they are not. This is what it will look like:

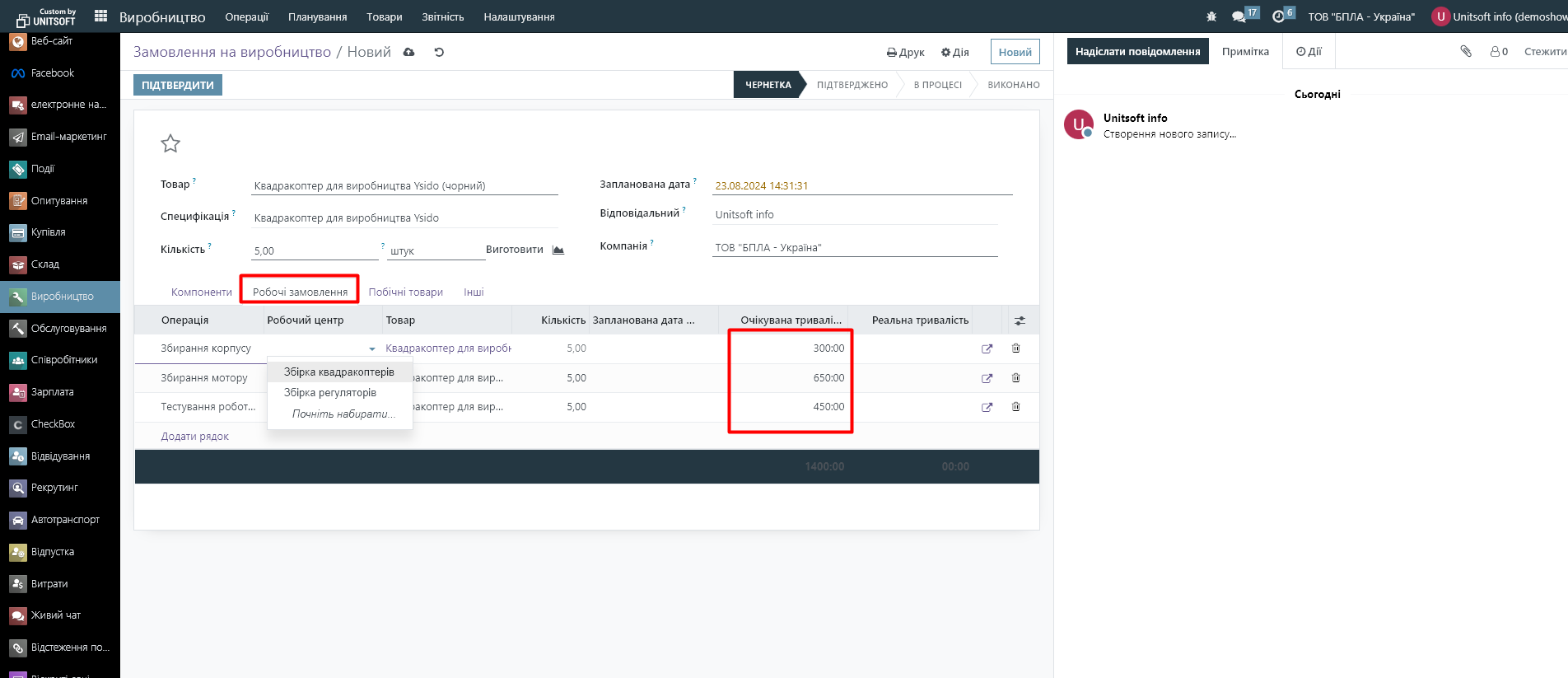

The "Work Orders" tab calculates the expected production duration. It also indicates the work center where production is planned. If necessary, this work center can be manually changed.

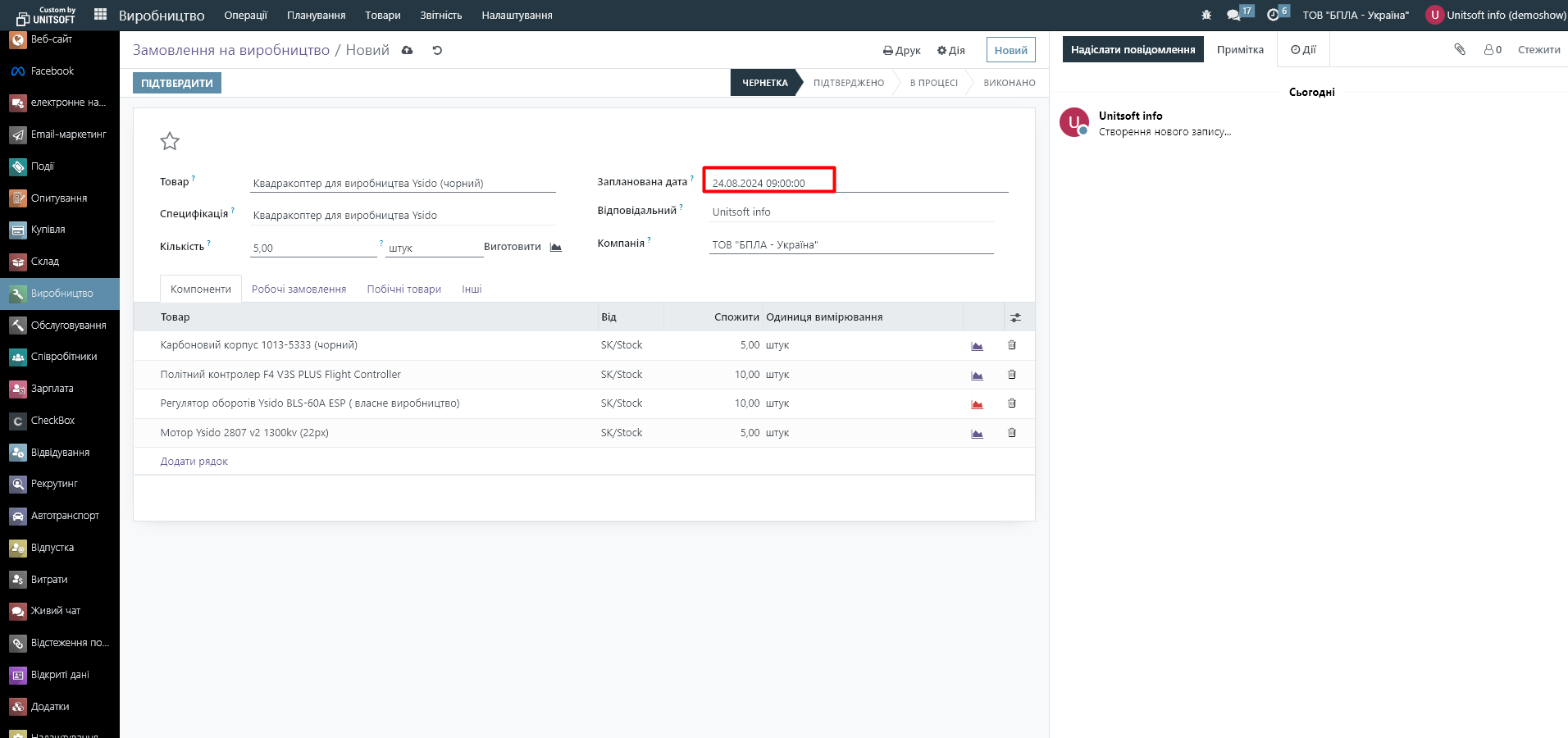

In the "Planned date" field, indicate the date and time when we plan to start work on production.

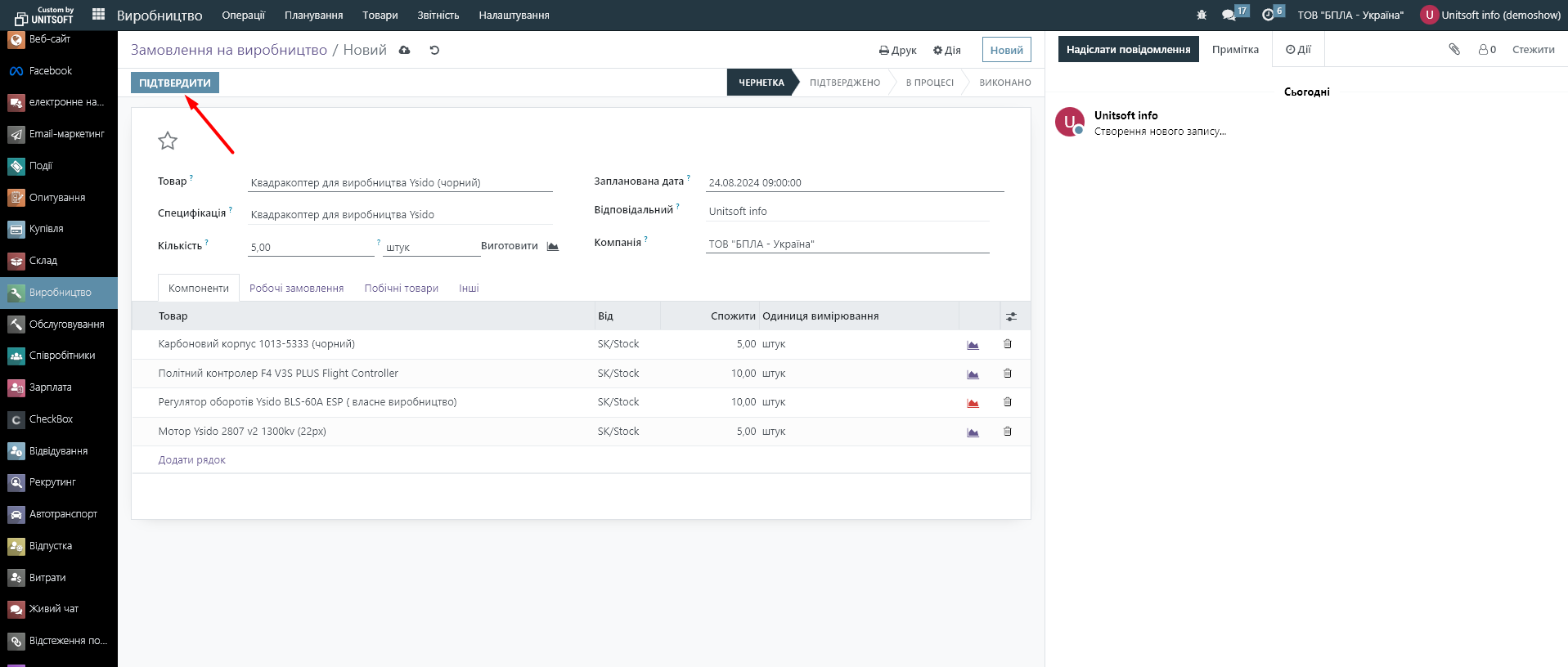

Click "Confirm":

Display of the fact of product release

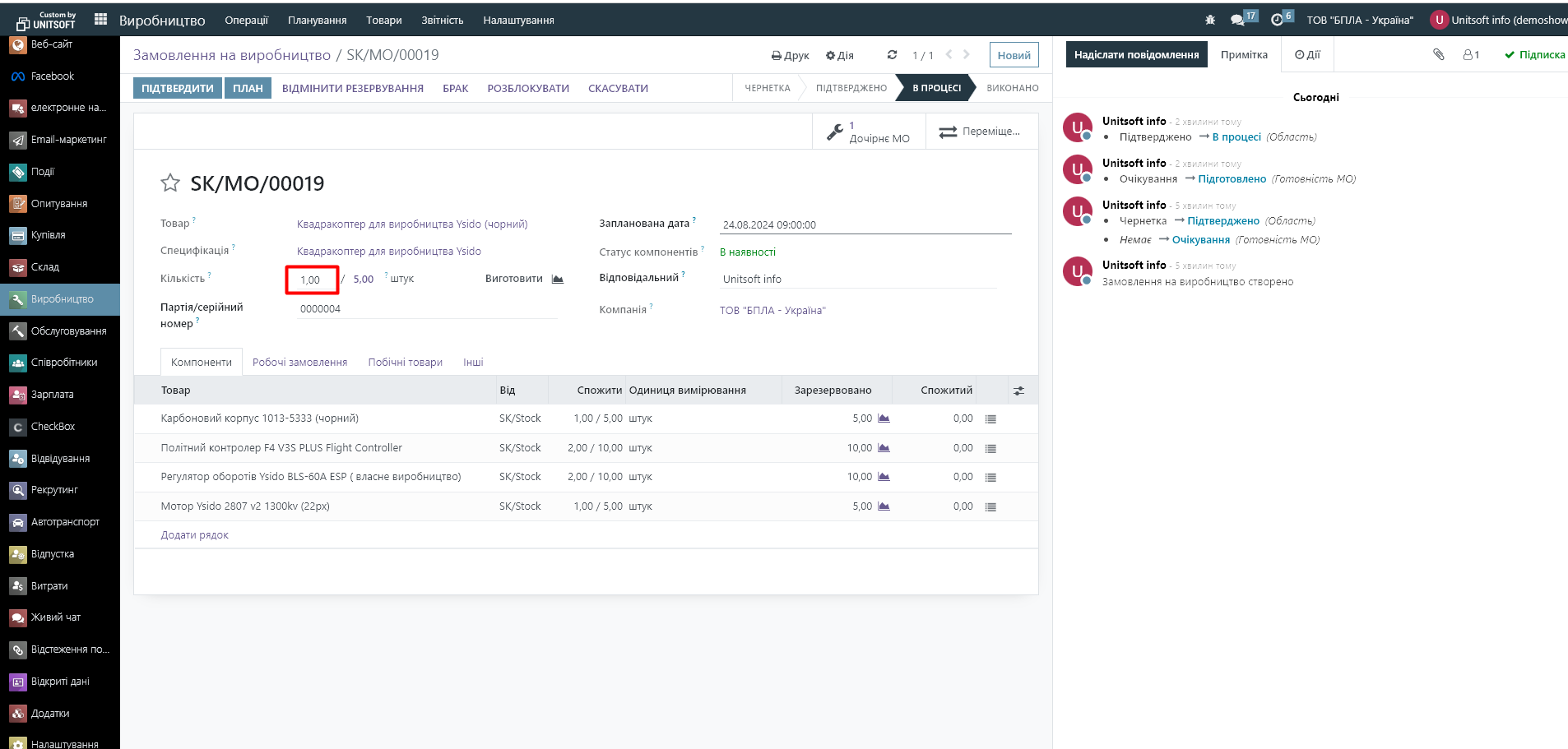

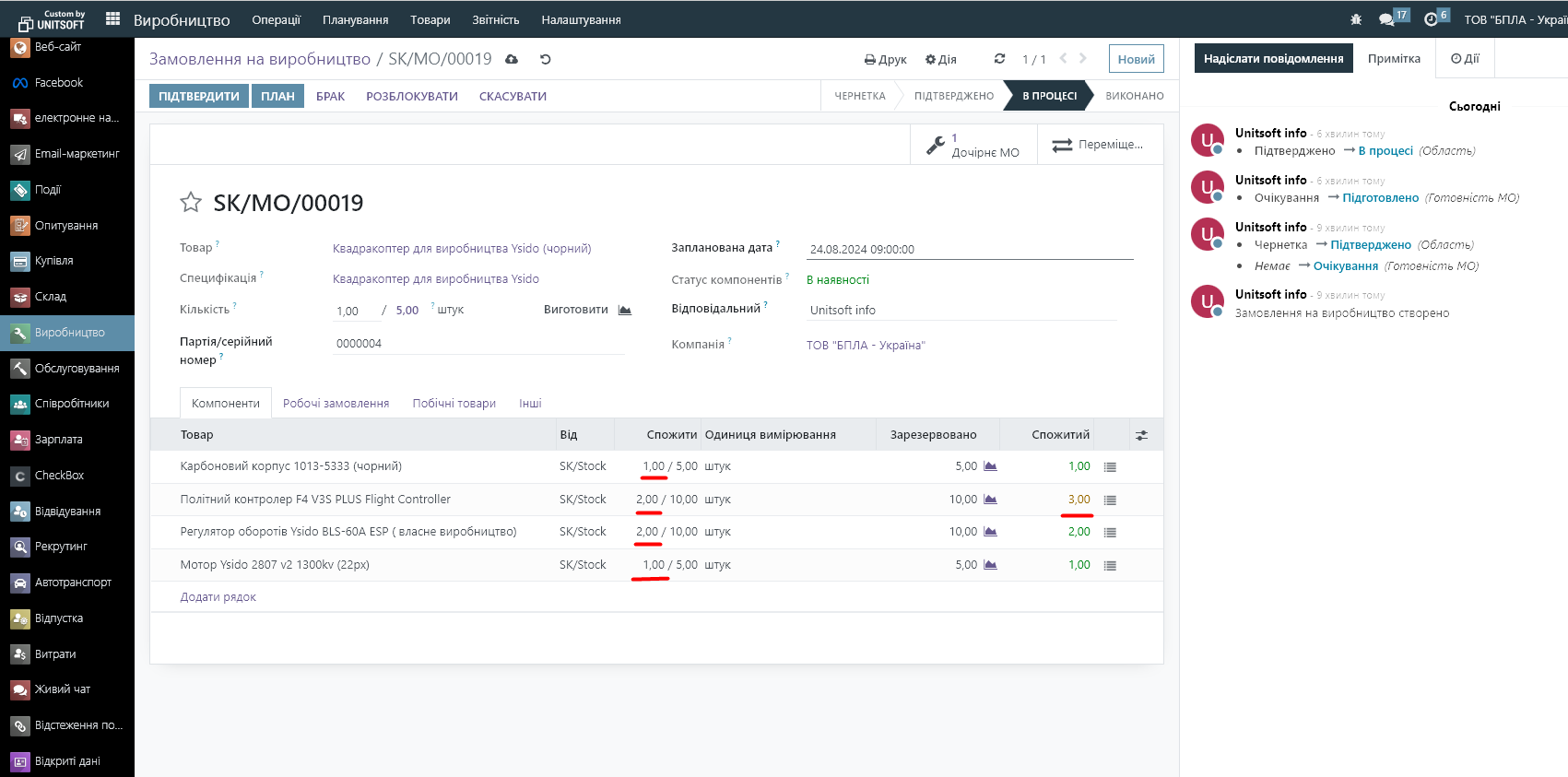

After confirming the Production Order, we can reflect the fact of the release of finished products.

To do this, in the "Quantity" field, we indicate the number of products that we actually produced:

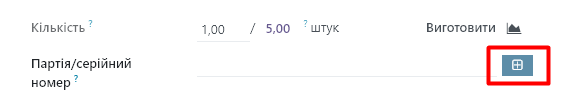

If your finished products are accounted for by batches/serial numbers, then we create a batch/serial number for the finished product:

At the same time, the planned amount of raw materials consumed according to the specification will be automatically calculated in the "Consume" column.

In the "Consumed" column, you must indicate the amount of raw materials actually consumed. This data will be automatically filled in according to the norm, but if necessary, you can manually change it:

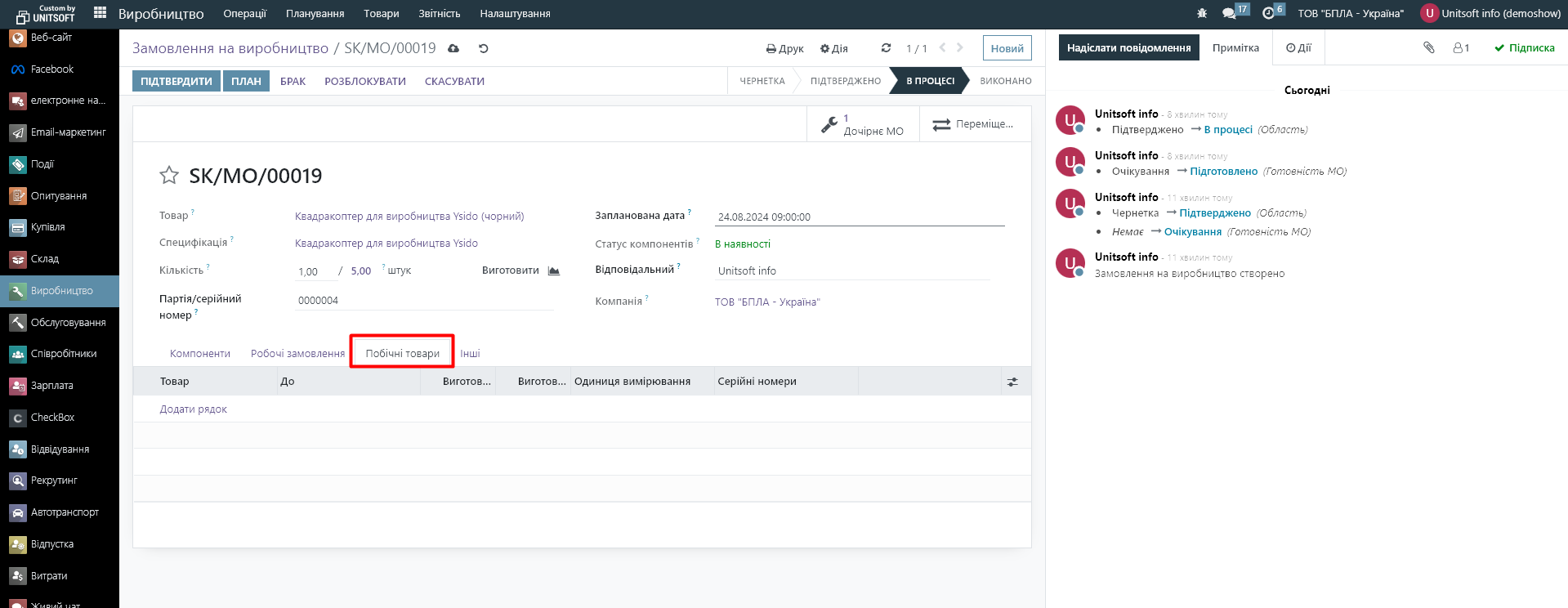

If there are any by-products in the production process (for example, shavings that can be sold later), we indicate them in the "By-products" tab:

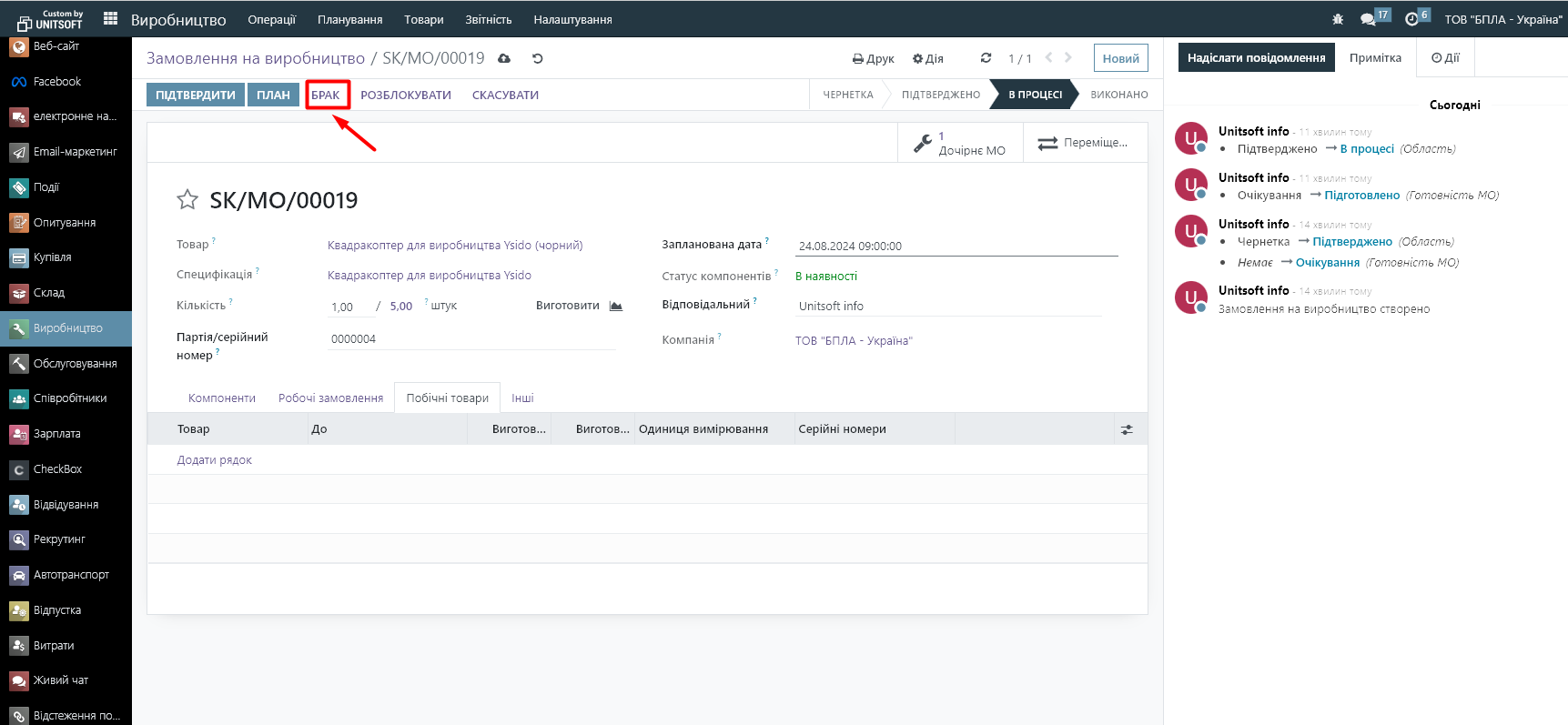

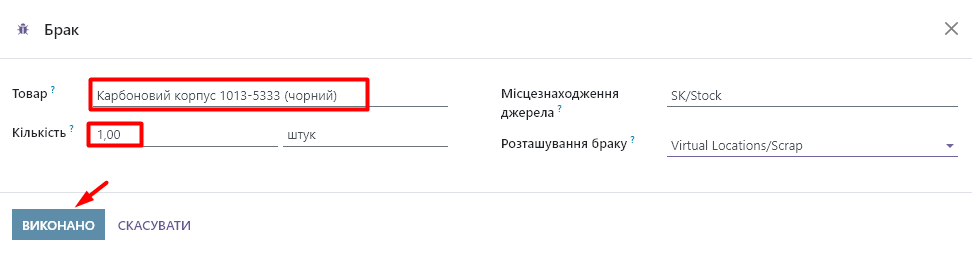

If during the production process it is necessary to write off a defect in raw materials, then click on the "Defect" button:

We indicate the raw material for which a shortage was detected, its quantity. We click "Done".

Finished goods shortages are reflected in the same way, but after production is complete.

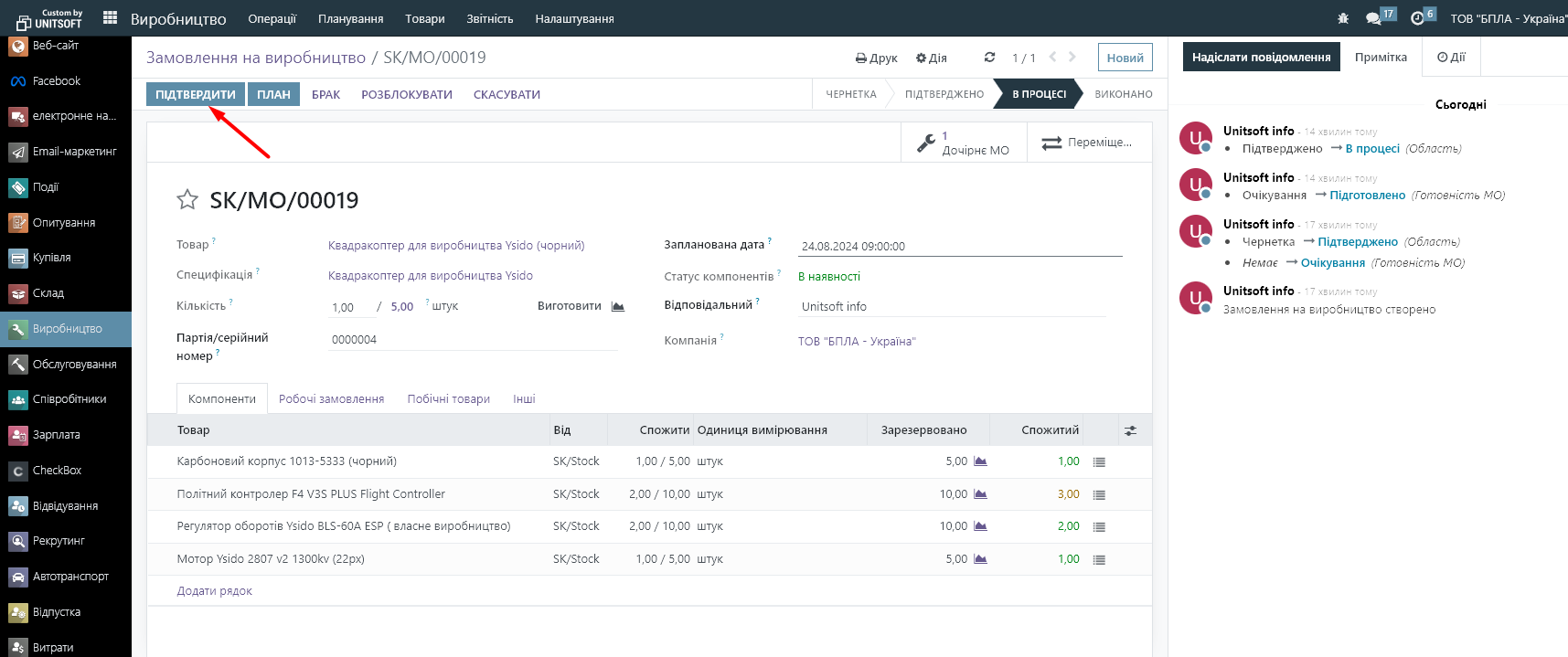

To complete production, click "Confirm".

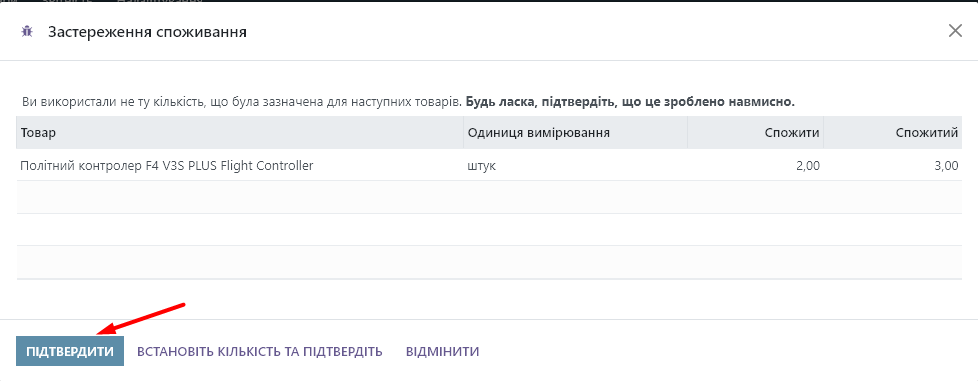

If you had deviations from the plan in terms of the amount of raw materials consumed, the following message will be displayed:

We check the information and click "Confirm".

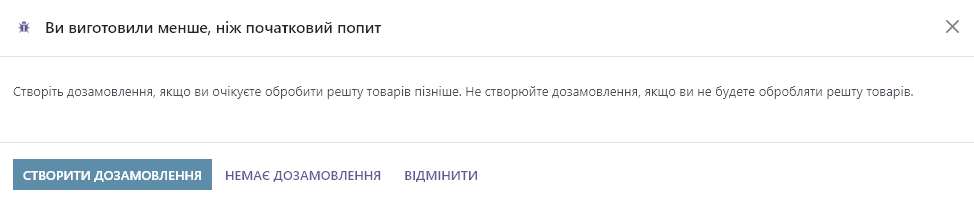

If you had deviations from the plan in terms of the quantity of finished products, a message will pop up asking whether it is necessary to create a reorder for the production of the under-produced quantity of products:

We choose our option

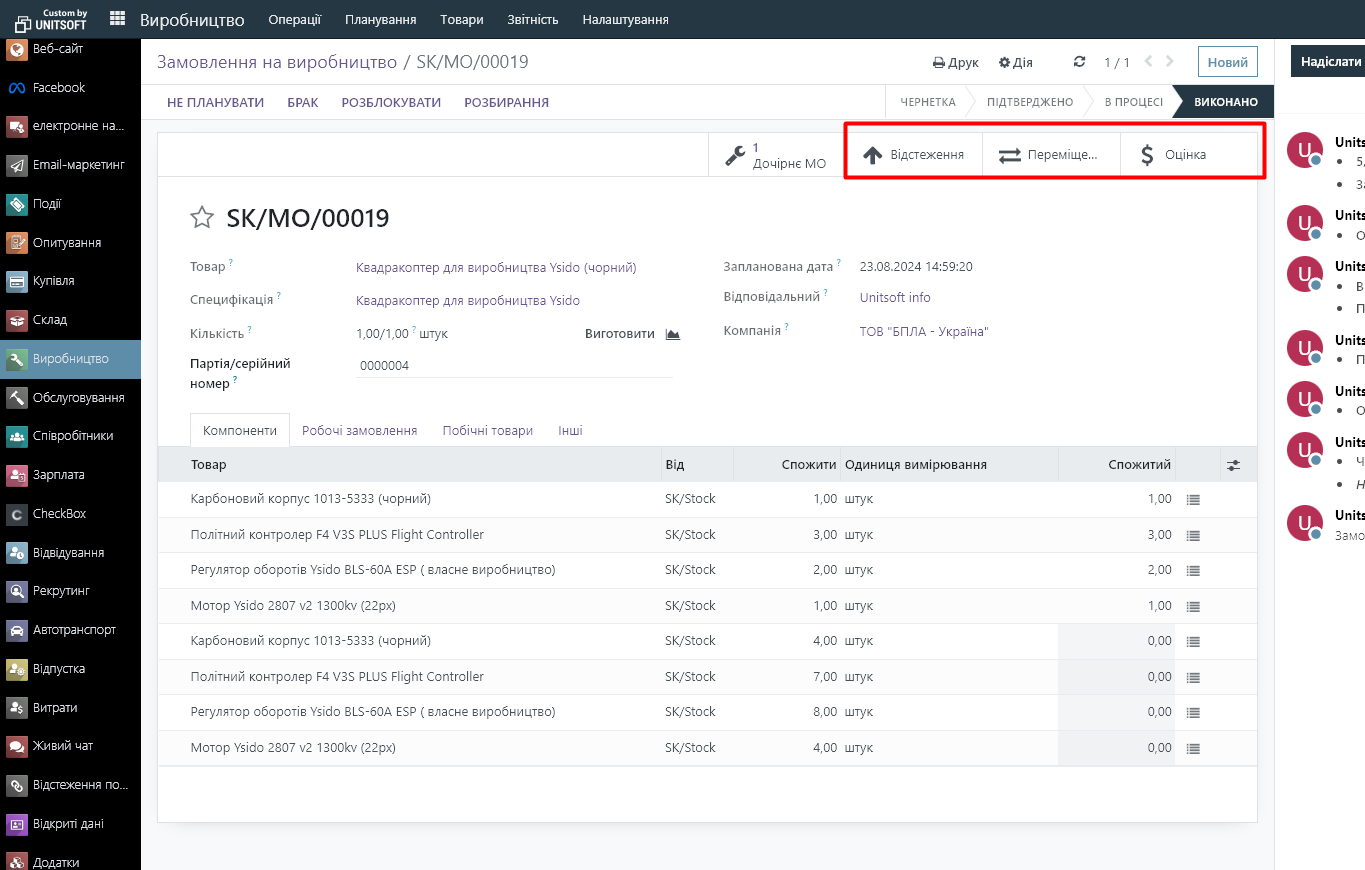

The production order will change to the status "Completed" and a link will appear to information about the calculation of the cost of finished goods and warehouse movements performed: