Subcontracting is the transfer of production of products or part of the production process to a third-party contractor. In Odoo Community, this tool allows you to automate work with subcontractors: control materials, finished products and the entire movement of goods. This is convenient when you want to reduce the load on your own production or use the services of specialized partners.

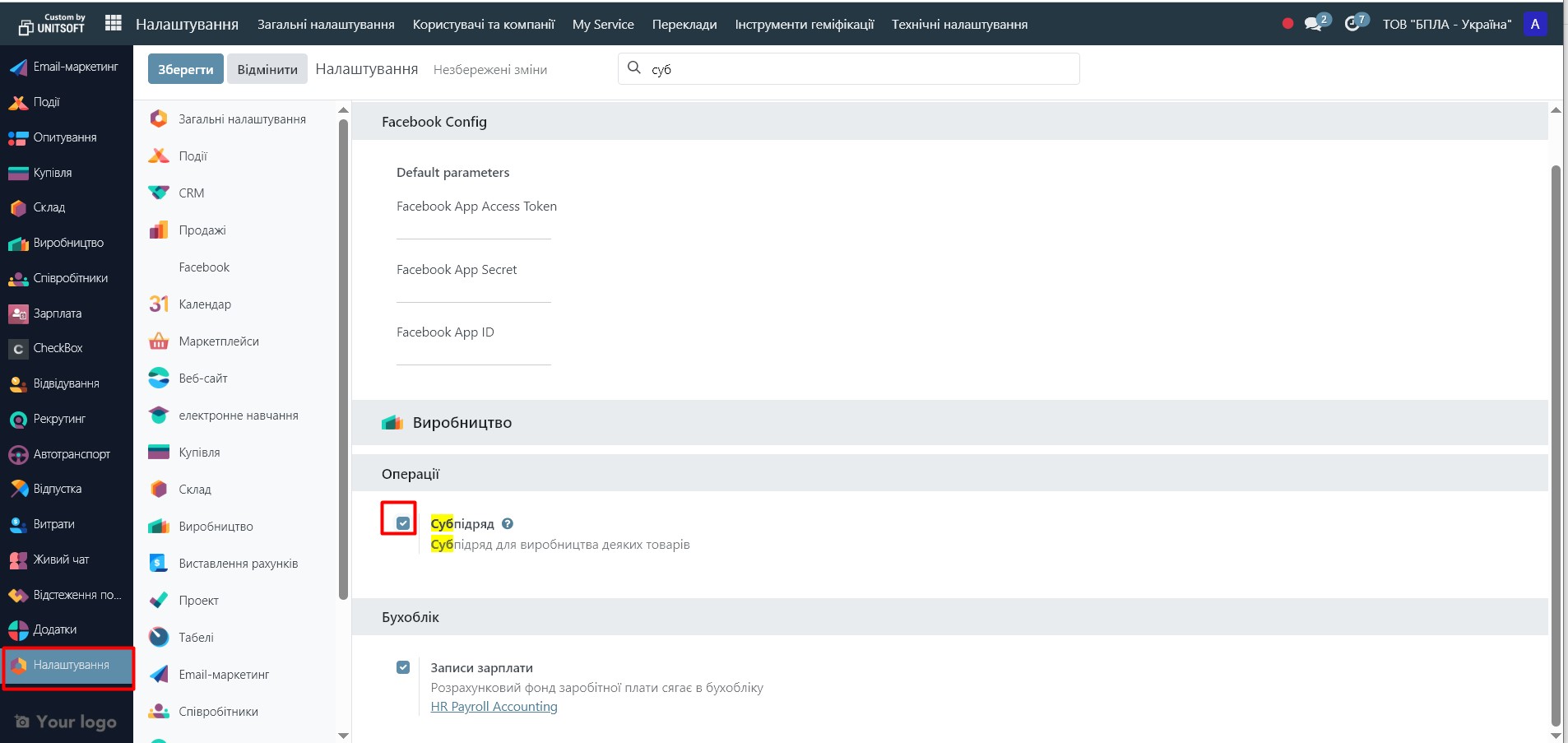

Step 1. Enable subcontracting

Go to the "Settings" module. Use the search bar to find the "Subcontract" option and check it:

Click the "Save" button.

Step 2. Set up the specification (BoM)

A subcontract bill of materials (BoM) is a document that specifies the composition of the finished product and the materials required to manufacture it.

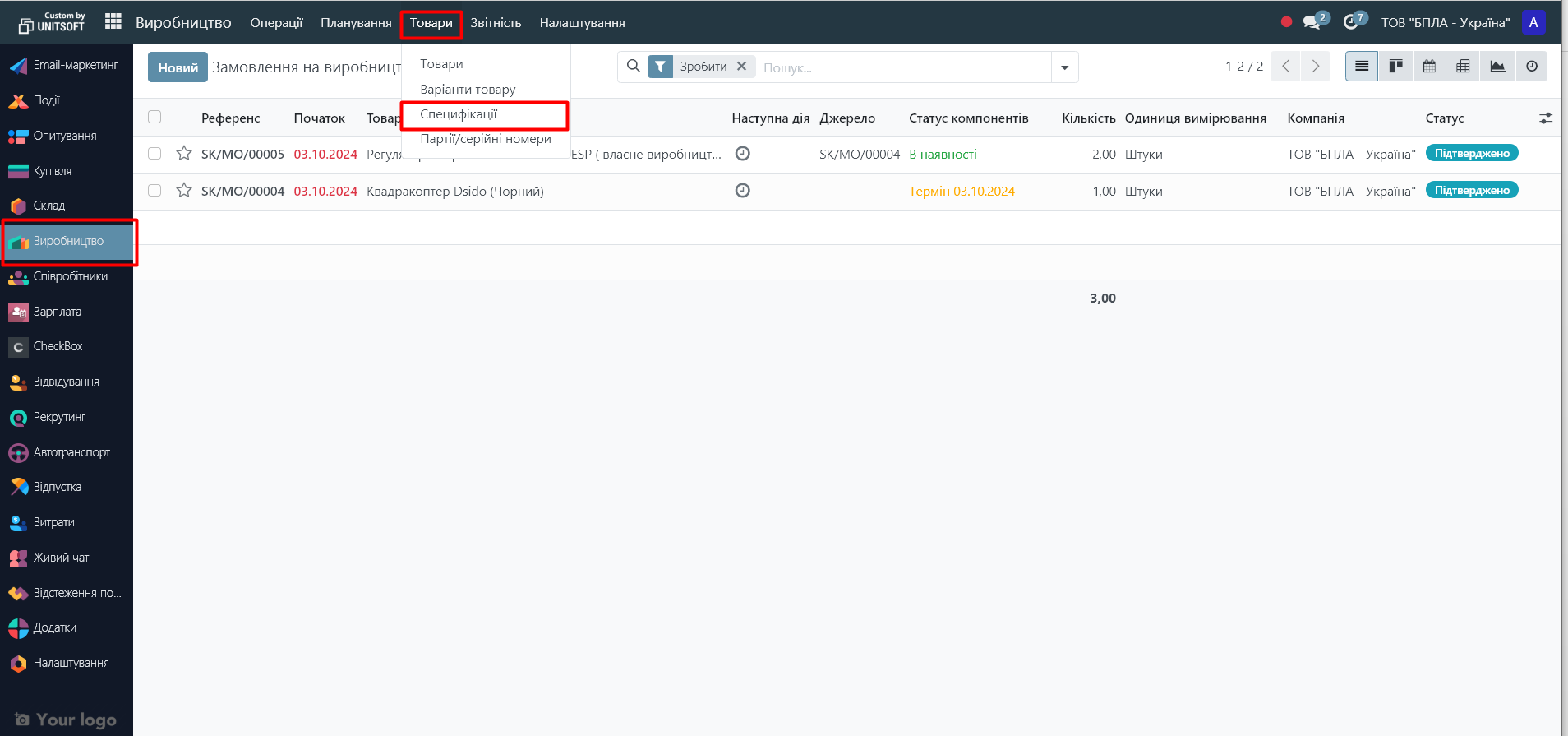

1. Go to the "Production" module - "Products" menu - "Specifications":

Click "Create."

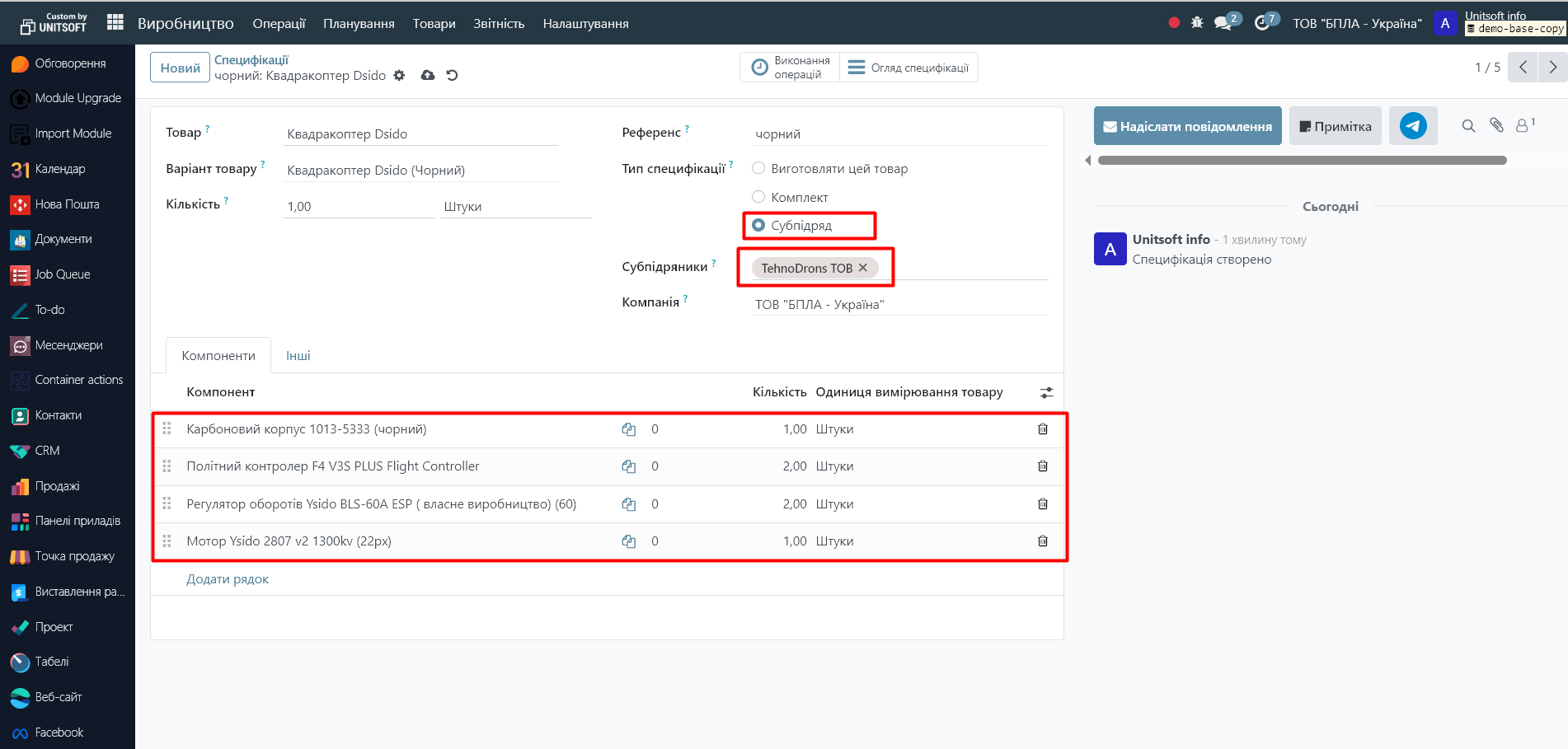

2. In the "Specification Type" field, select "Subcontract".

3. In the "Subcontractors" field, add the appropriate supplier.

4. Add the components (raw materials) needed for production.

The following settings will depend on the type of subcontract.

Odoo supports two models of working with subcontractors, which differ in the mechanism for providing components:

1. Basic subcontracting – the subcontractor purchases the materials himself, or the transfer to the subcontract location occurs separately, regardless of the orders formed (for example, in large batches the day before)

2. Supply to a subcontractor by order – the company supplies materials from its warehouse separately for each subcontract order.

Scheme 1. Basic subcontract

How to set up

1. In the finished product card:

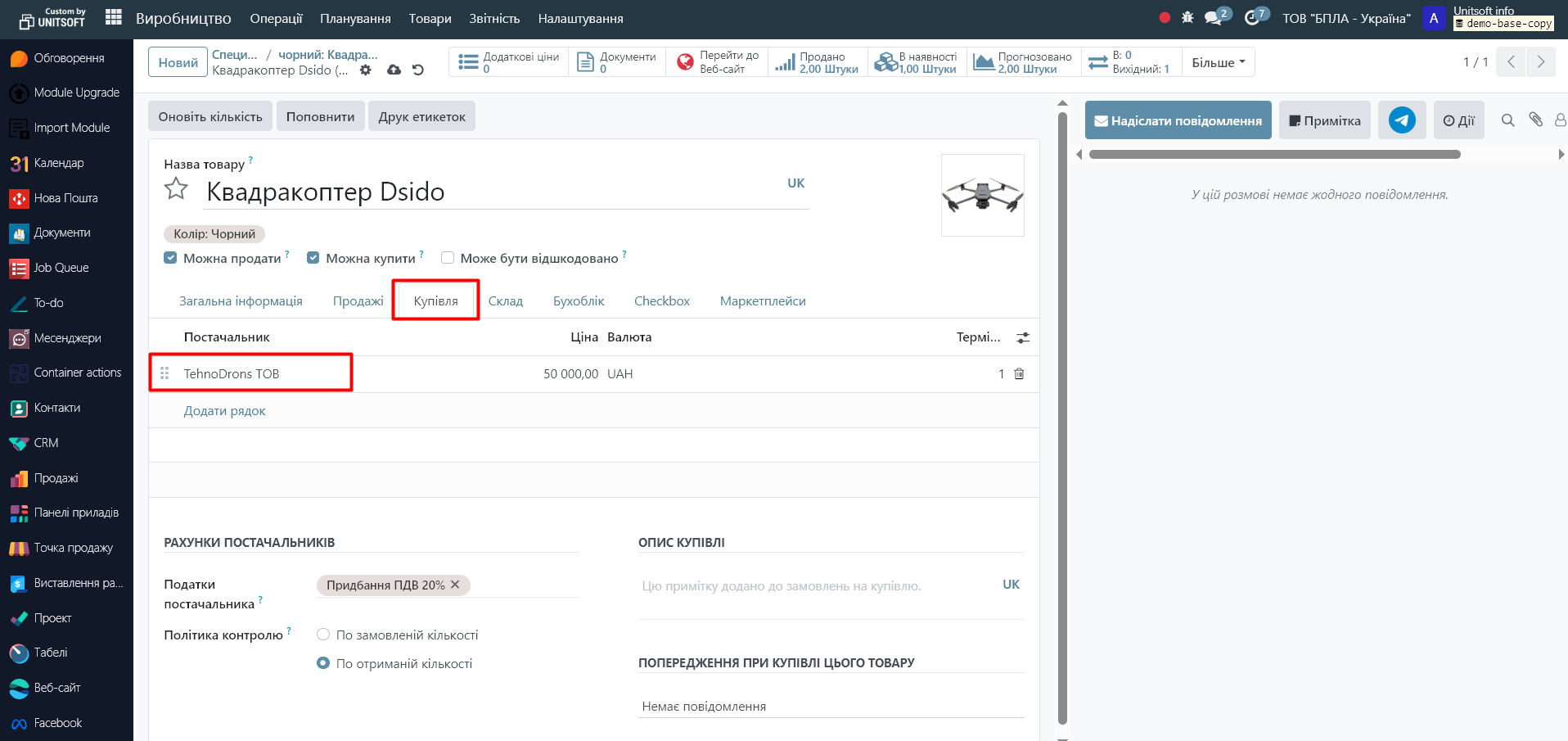

- o Purchasing tab → add subcontractor as supplier:

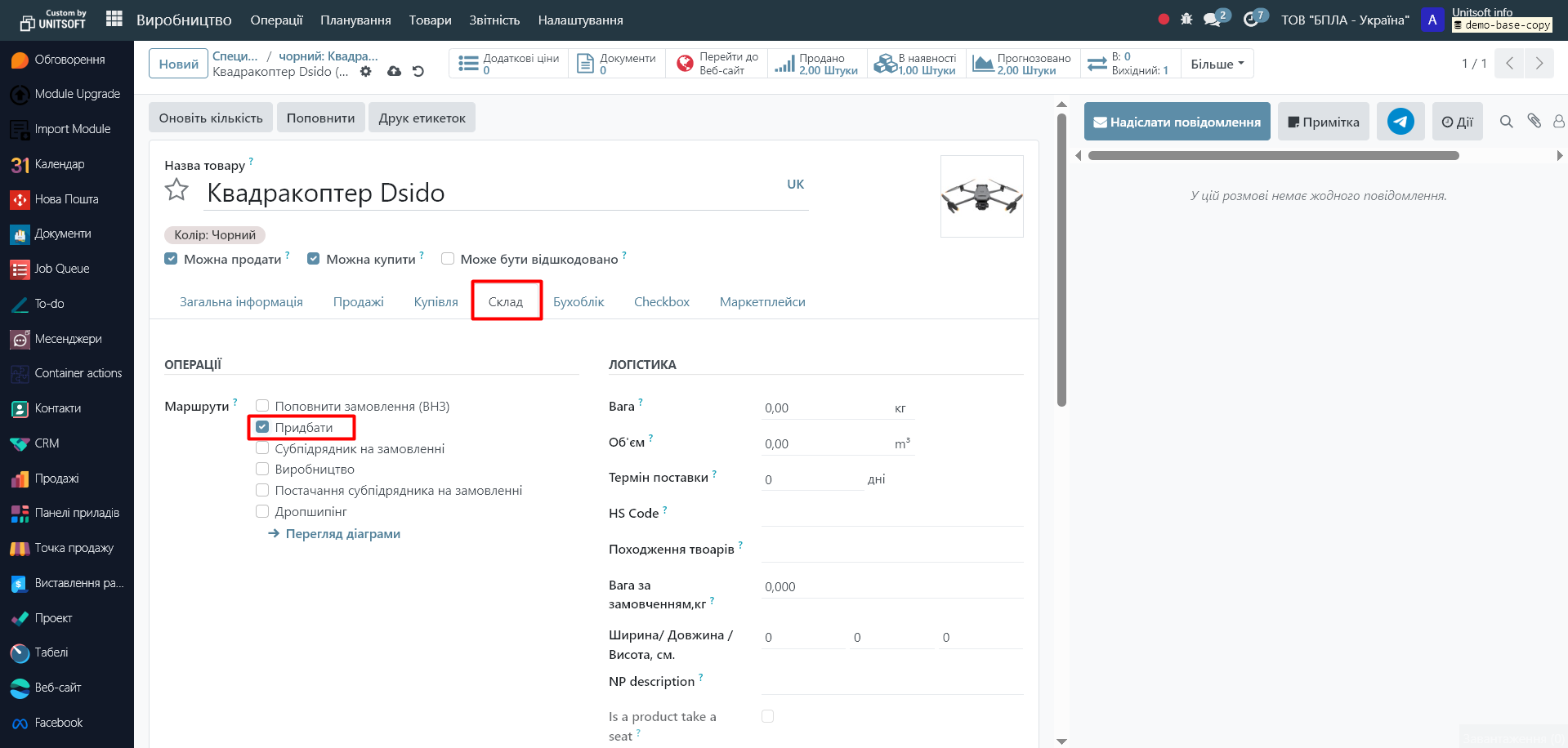

- o "Warehouse" tab → choose the "Purchase" route:

Workflow

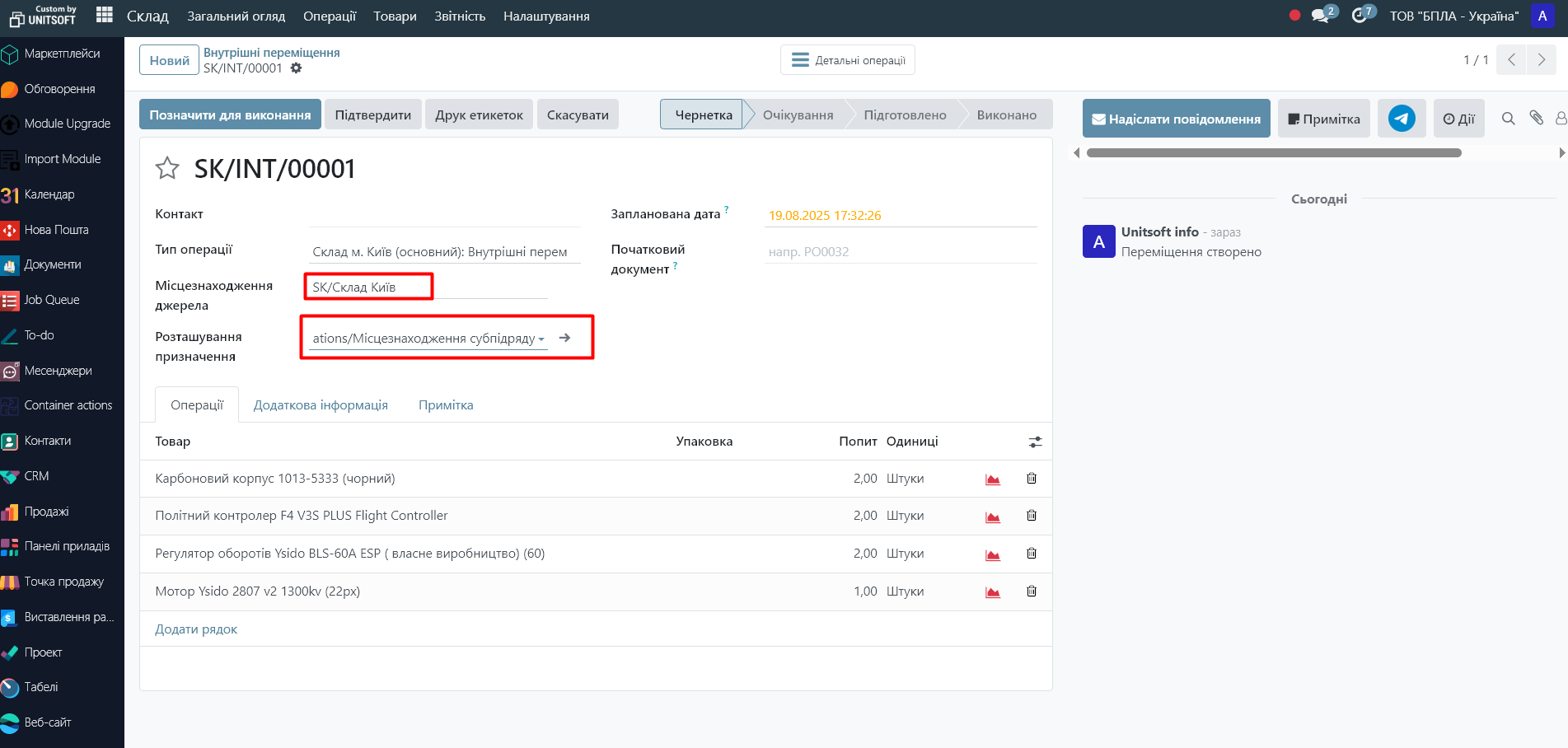

1. The subcontractor purchases materials independently or receives them from you separately, regardless of purchase orders (for example, in large batches). To reflect this transfer of raw materials from your company, the system creates inventory transfers to the subcontract location:

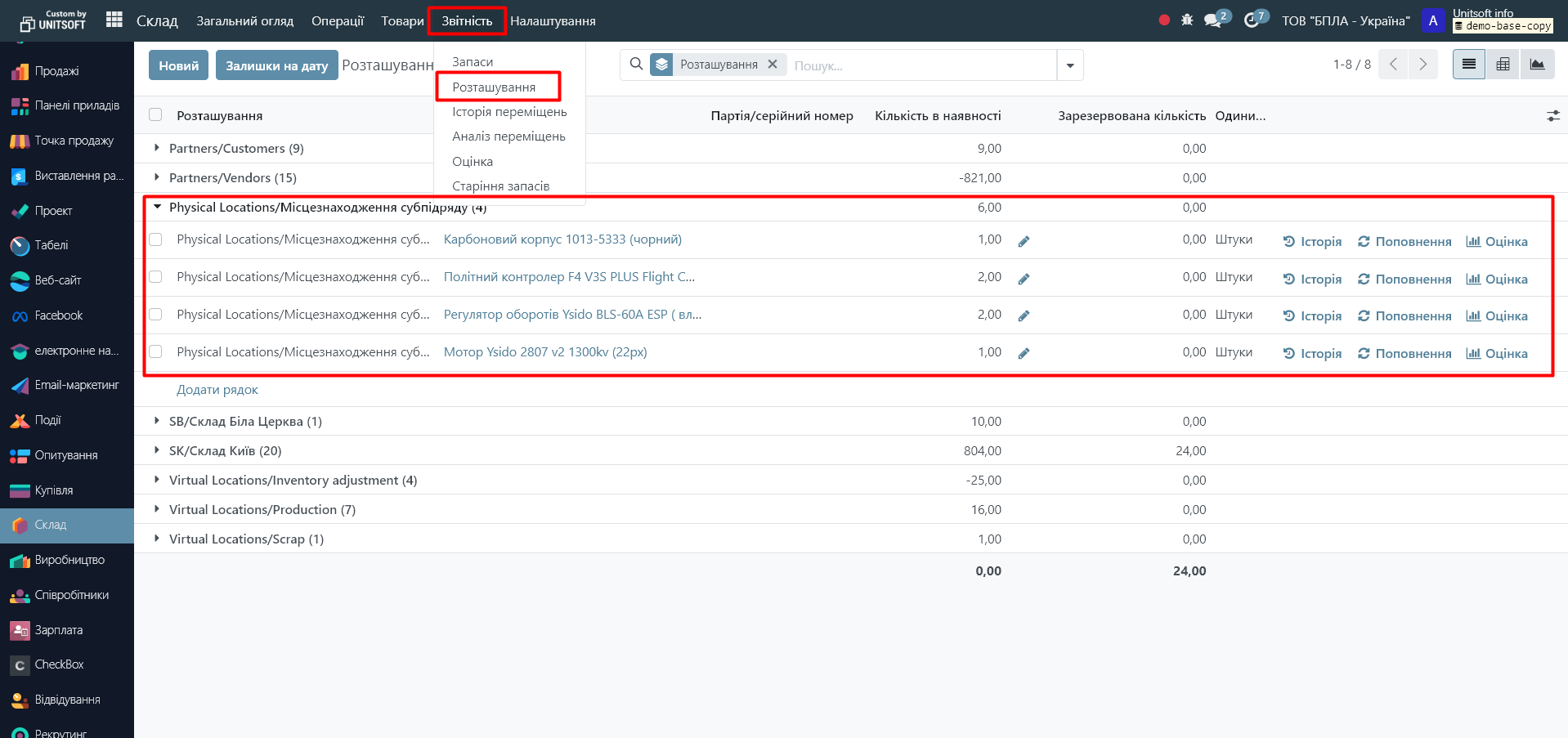

Please note that Odoo allows you to track raw material balances at the subcontractor's location:

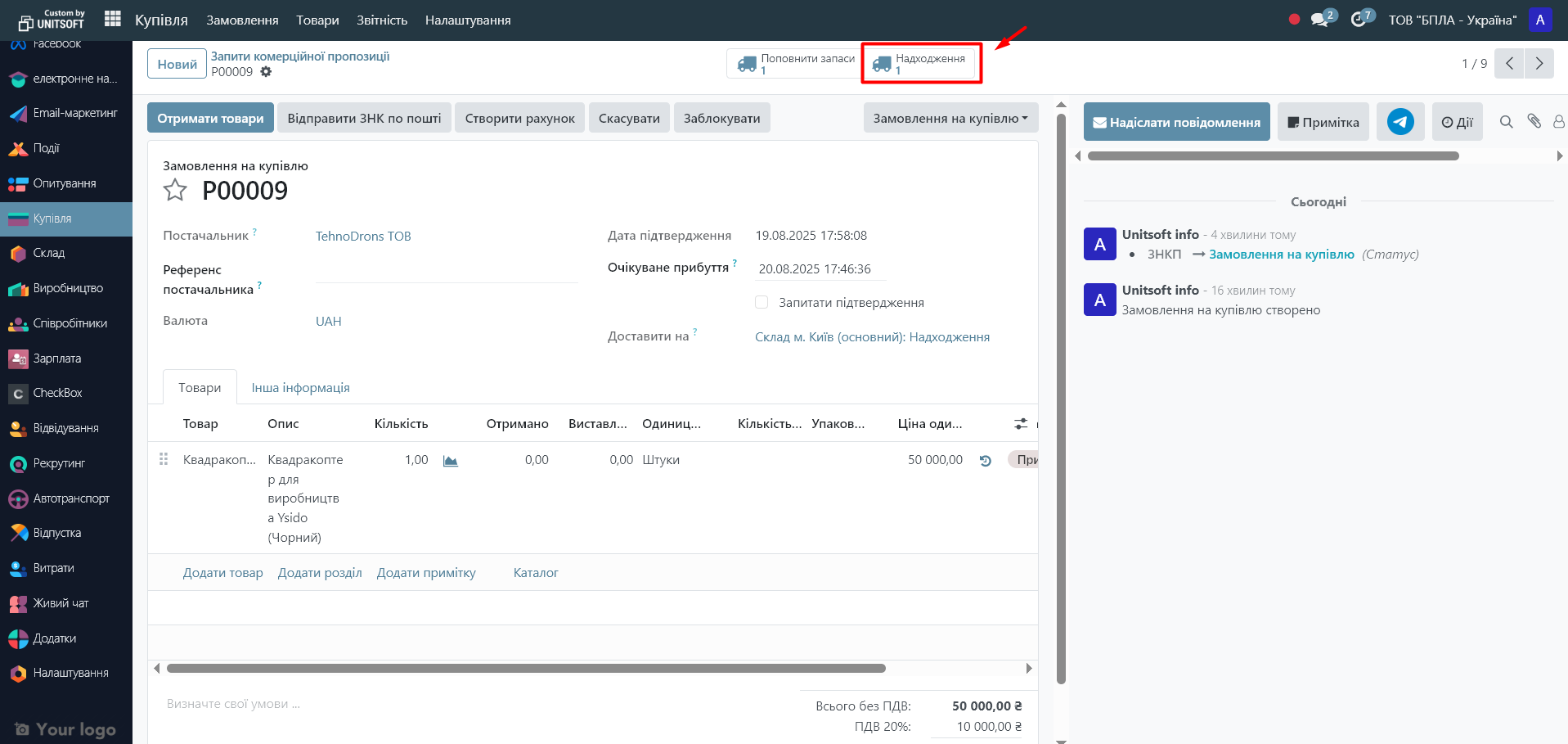

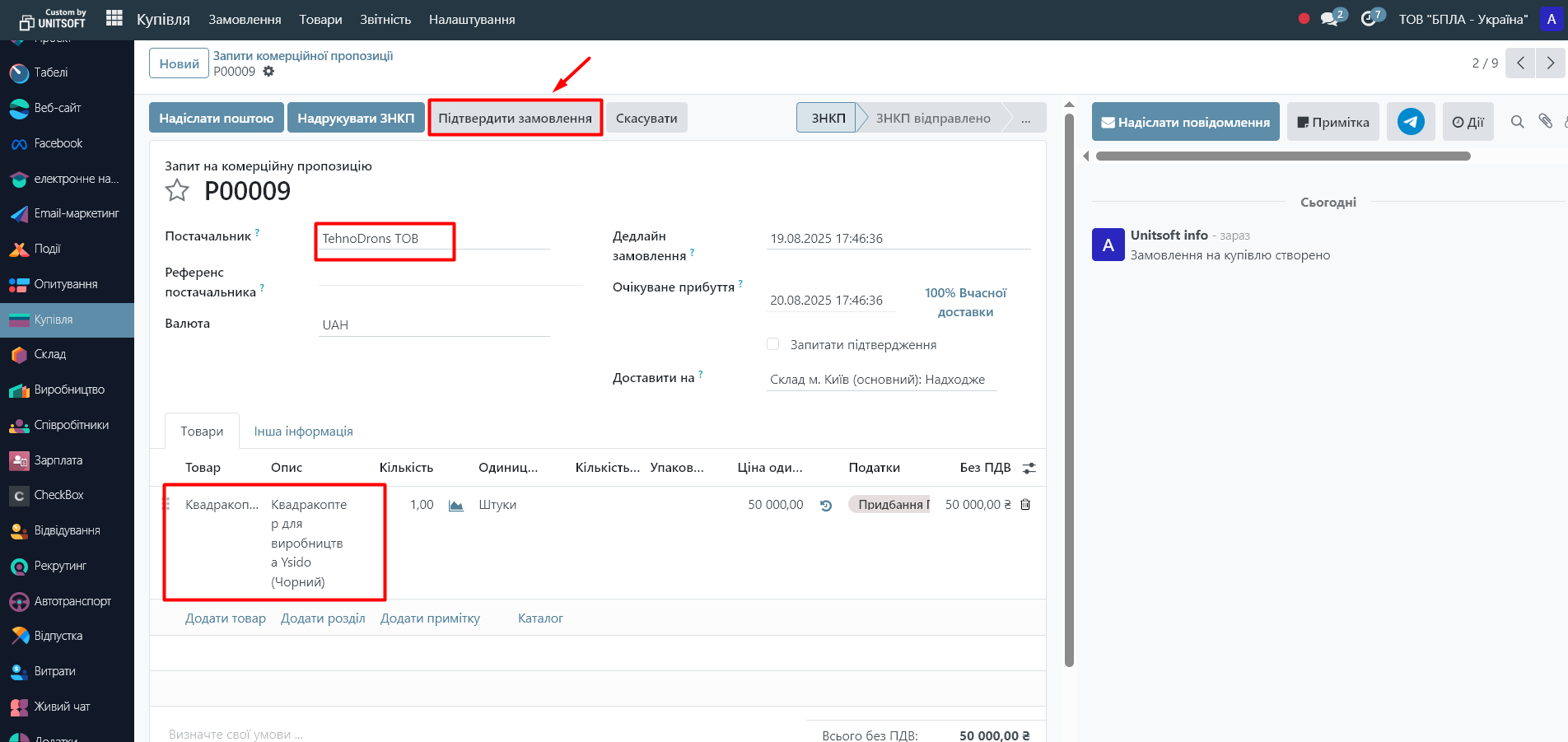

2. We create an order for the subcontractor to purchase goods.

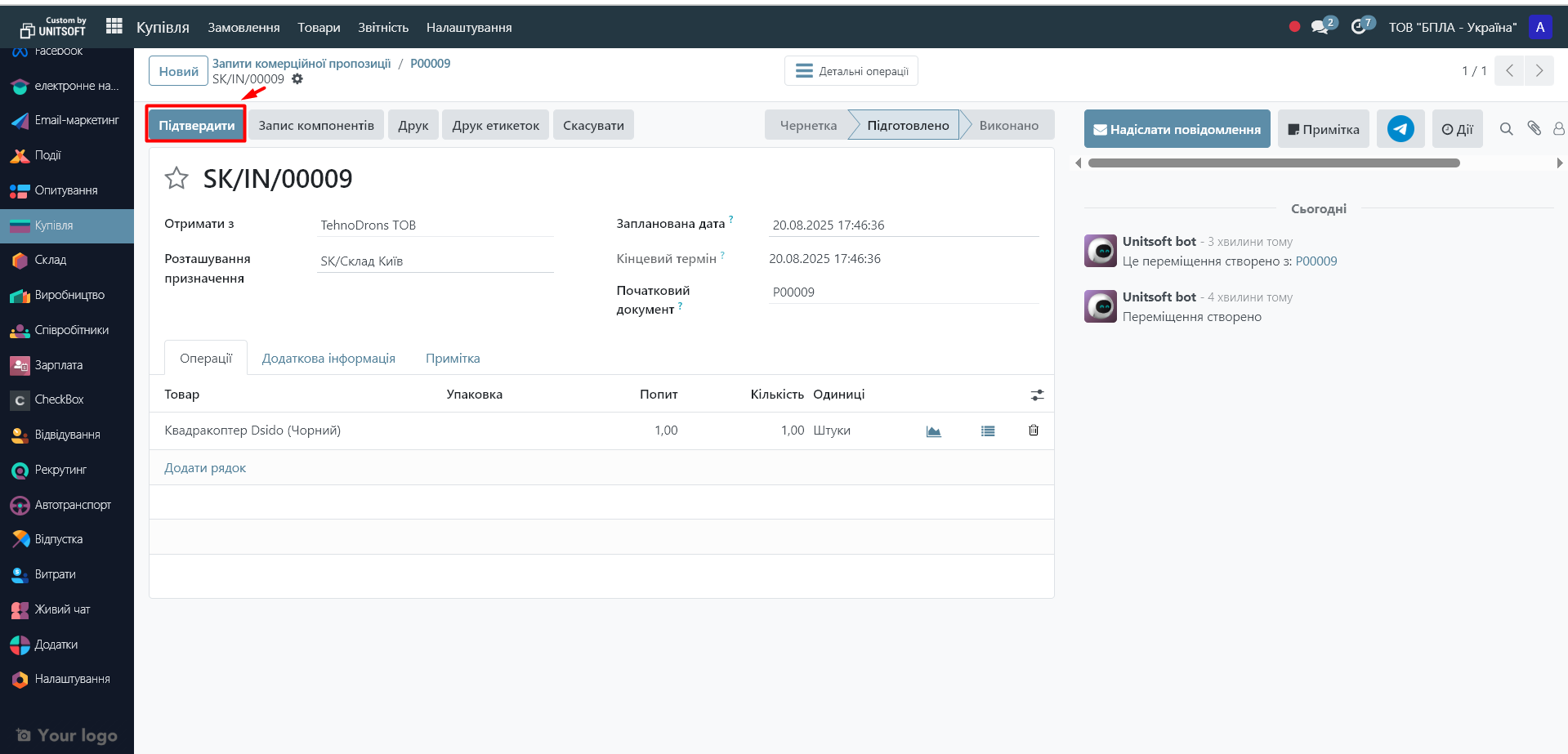

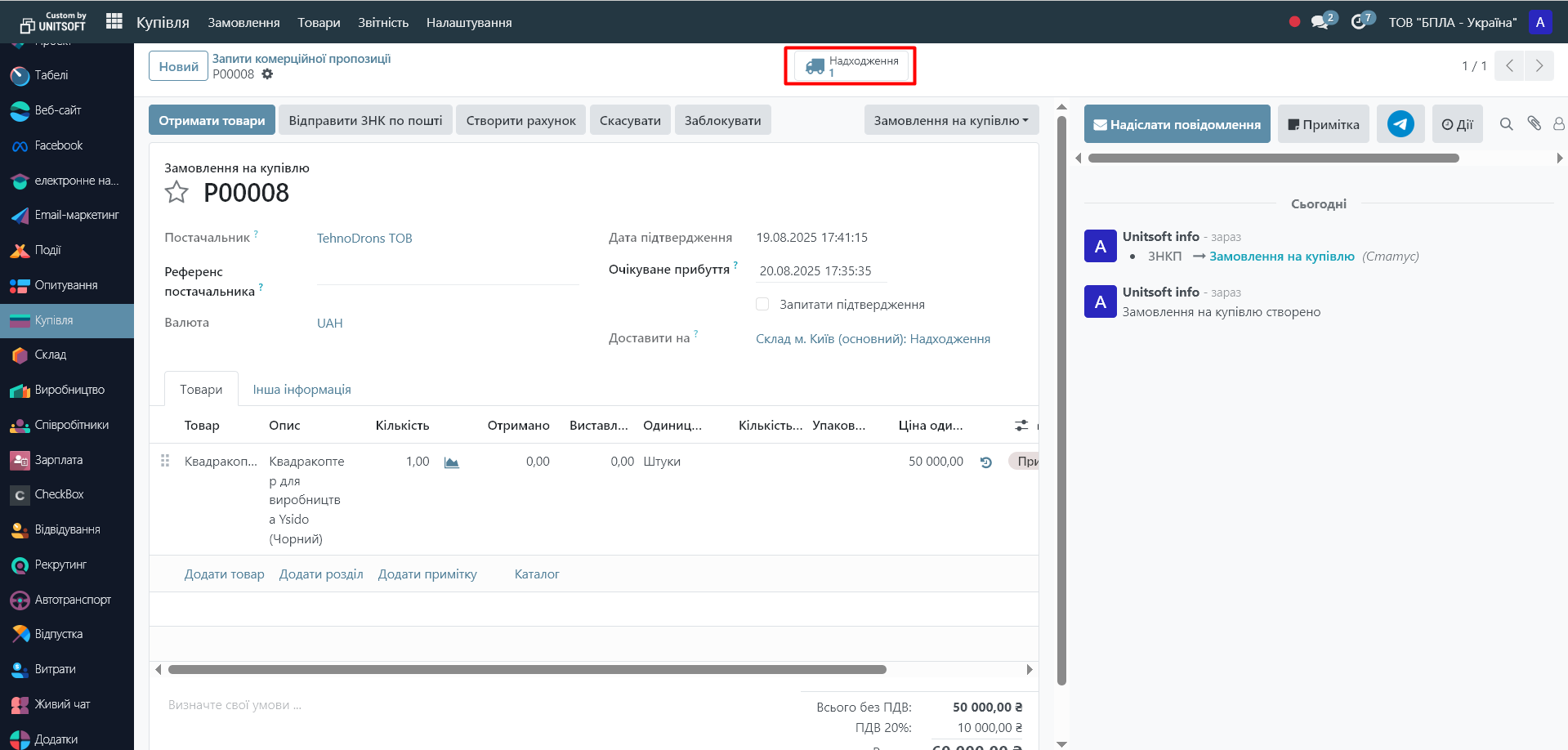

3. We receive finished products through the “Receipt” document:

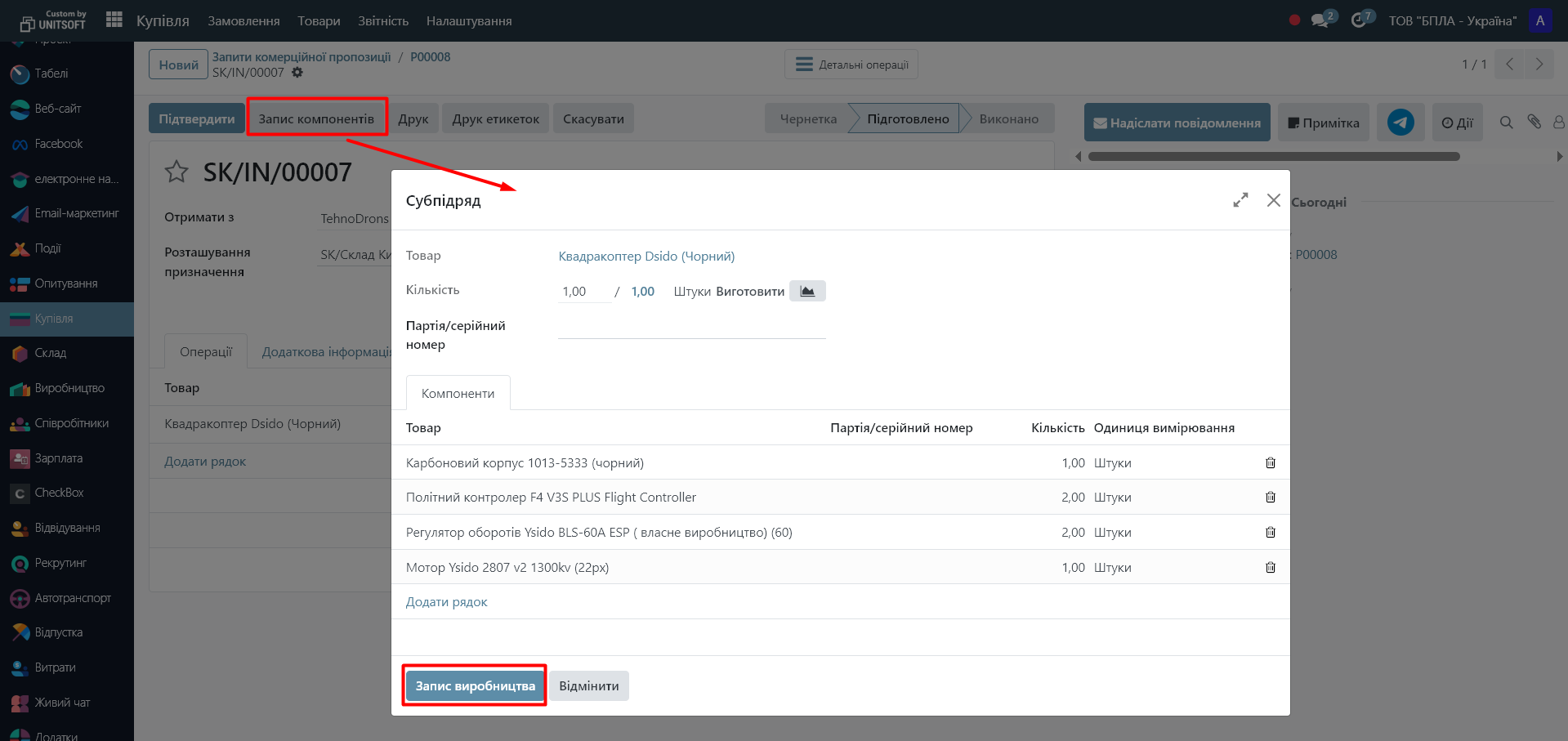

When you mark the fact of delivery (the "Confirm" button in the "Receipt" document), raw materials are automatically written off from the subcontractor's location according to the previously configured specification. If for some reason, raw materials need to be edited before writing off, this can be done via the "Record components" button:

Based on the results of confirming the "Delivery" document, finished products will be posted to your warehouse, and raw materials used in production will be written off from the subcontractor's location.

Scheme 2. Supply to a subcontractor by order

How to set up

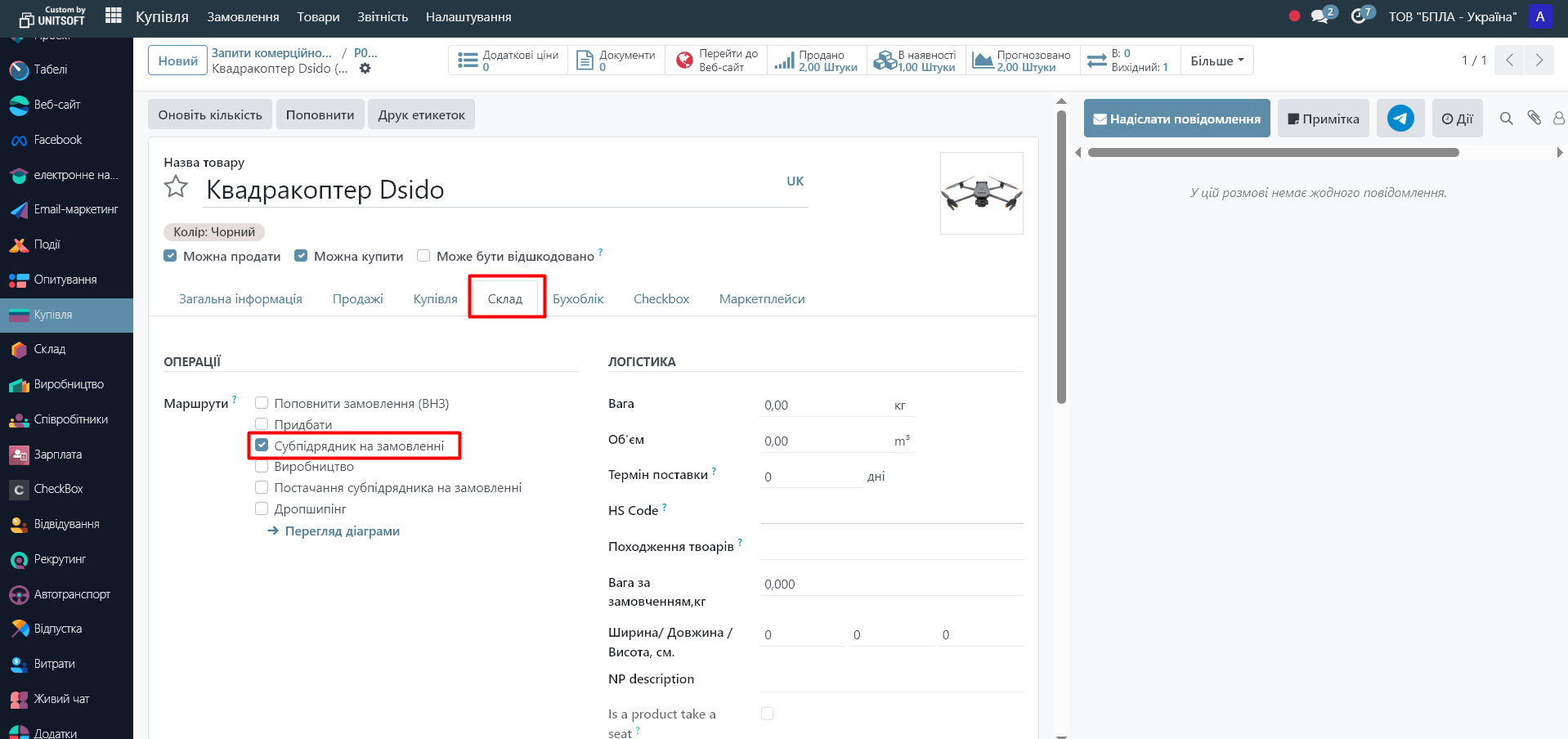

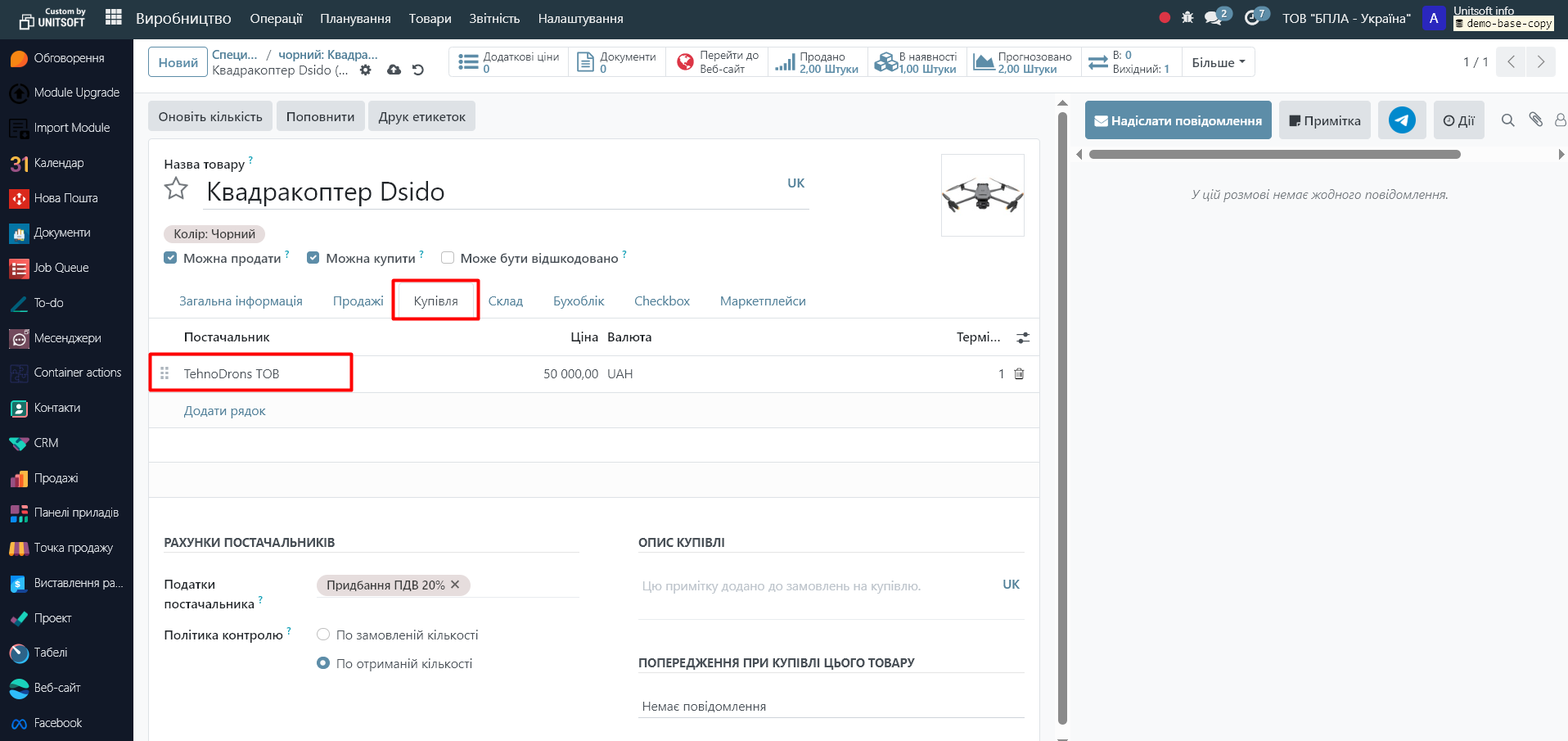

1. In the finished product card:

- o “Warehouse” tab → select the “Subcontractor on order” route:

- o Purchasing tab → add subcontractor as supplier:

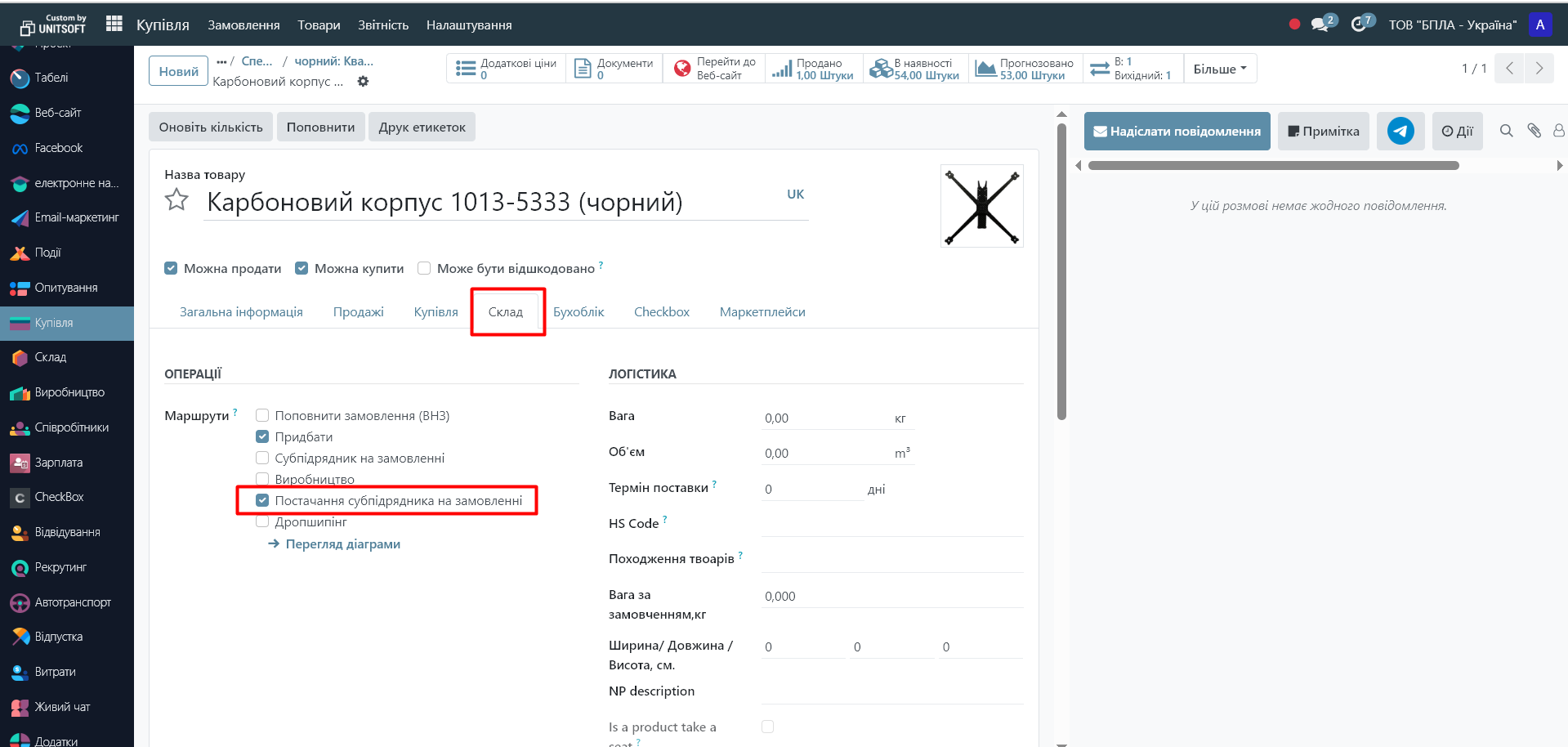

2. For each component of the specification → route "Supply to subcontractor by order" (can be configured at the product category level):

Workflow

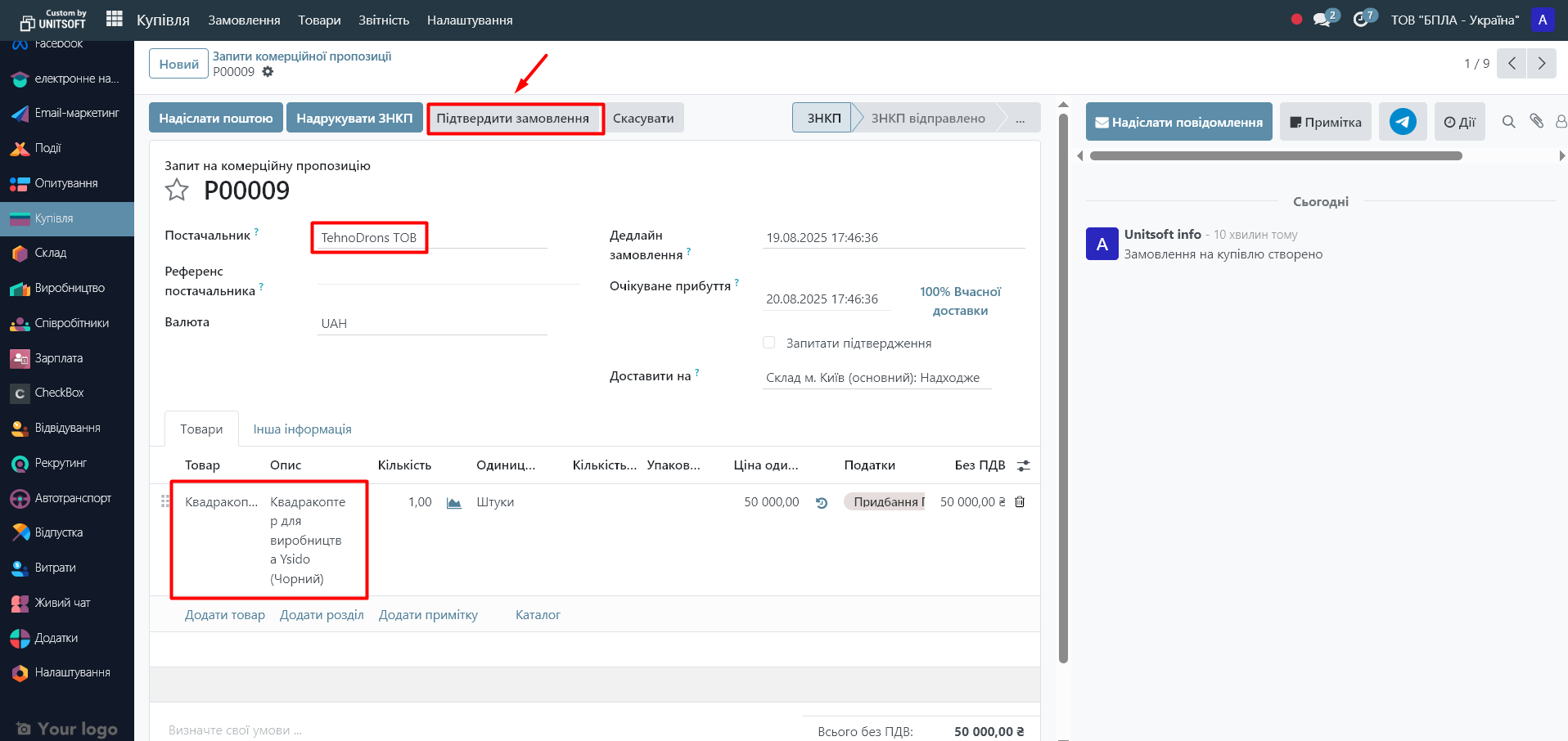

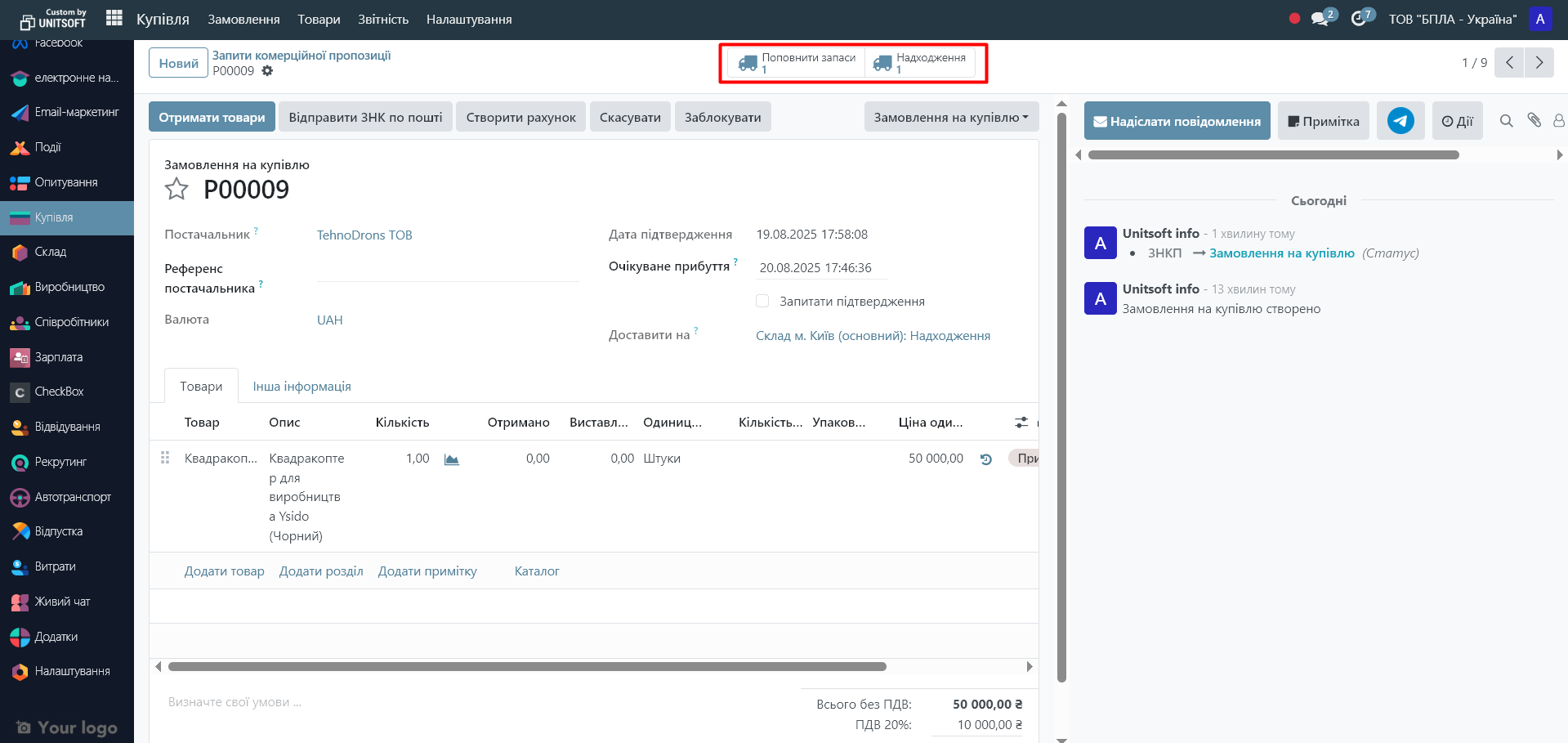

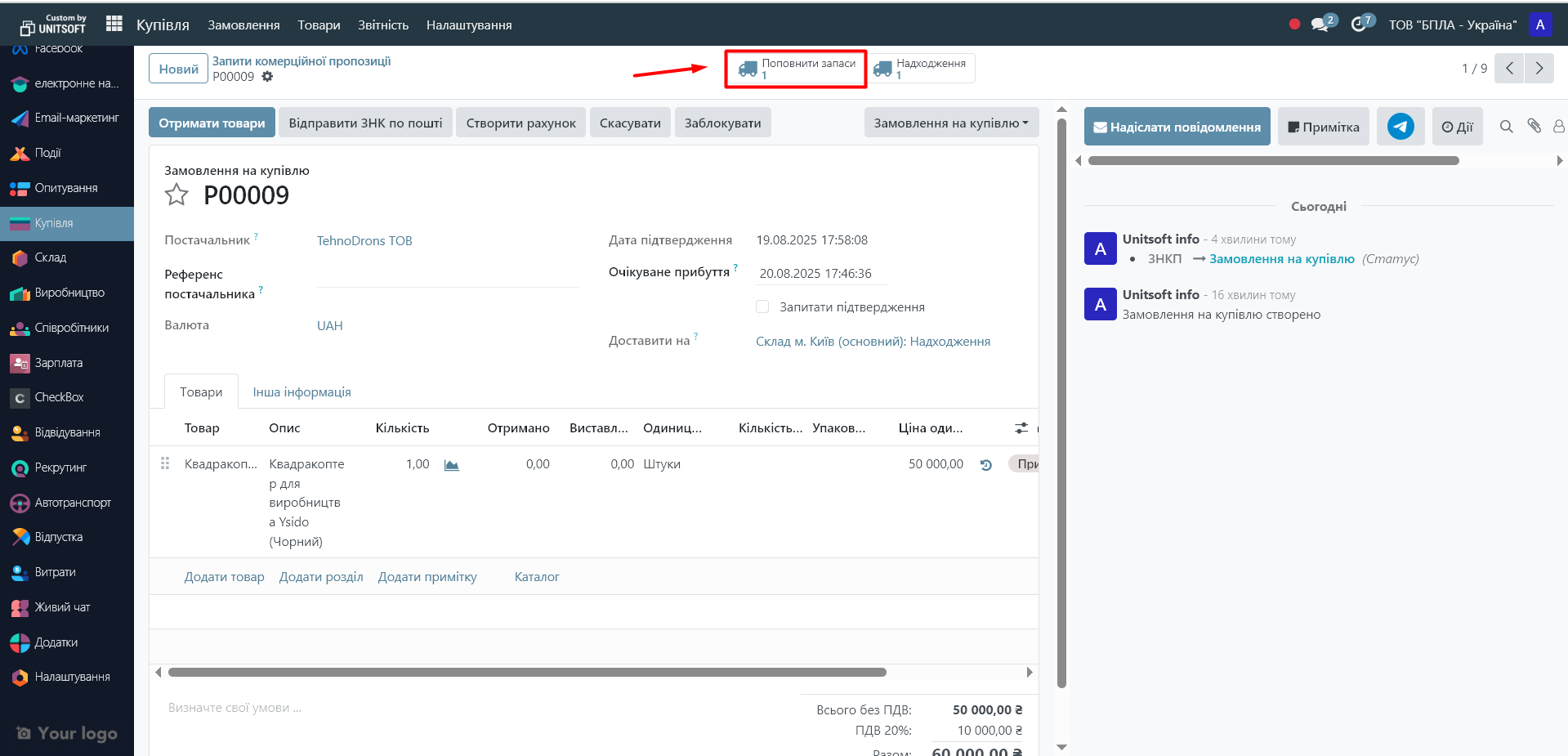

1. We create an order for a subcontractor to purchase goods:

2. Automatically generated:

- o moving materials from your company's warehouse to the subcontractor's warehouse,

- o a receipt for finished products.

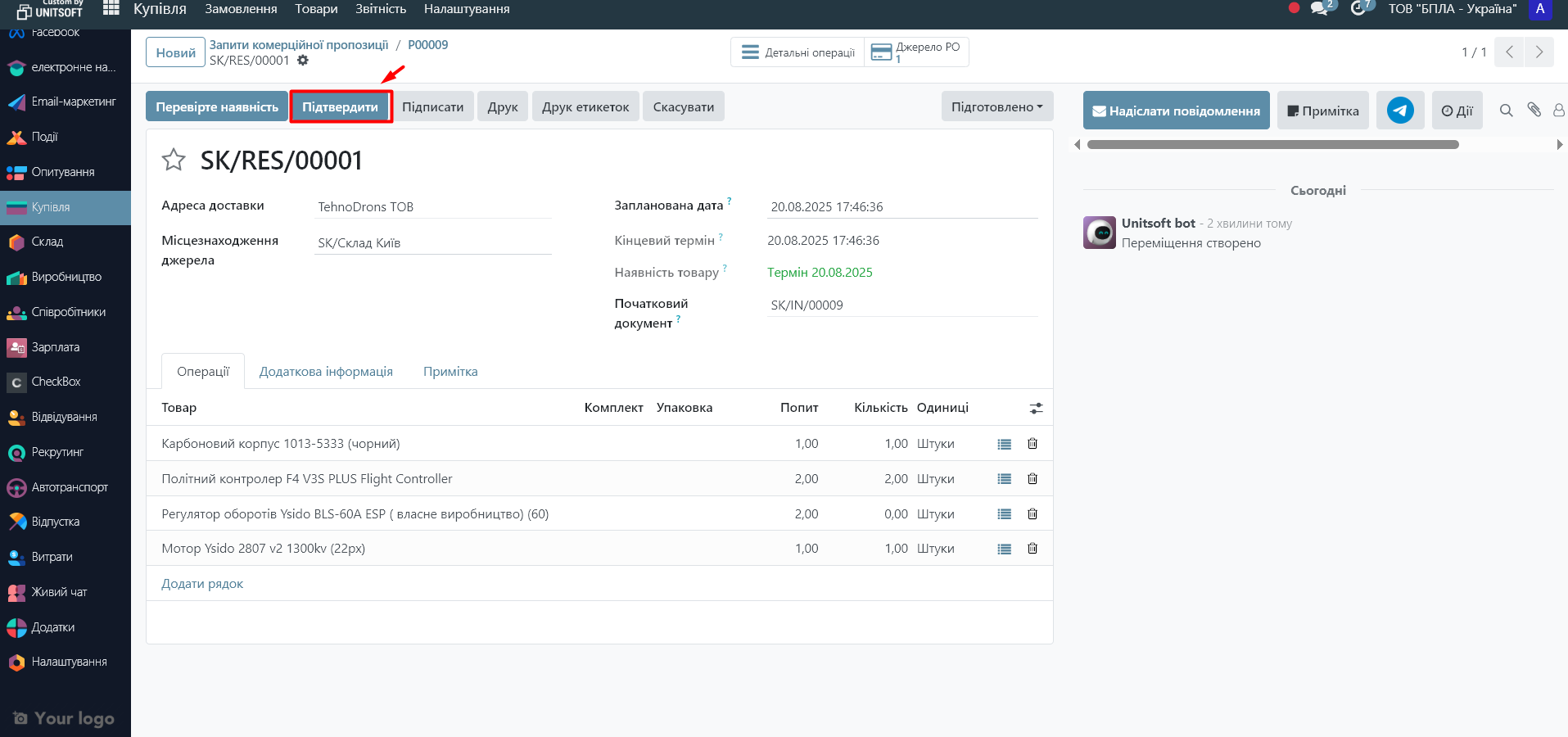

3. You send materials to a subcontractor:

4. After production, you receive the finished product: